Oriental Motor Asia Pacific Pte. Ltd. > Solutions_Wafer Transfer Box Equipment

EtherCAT probe function for Stepper Motor detection applications (Touch Probe)

|

Wafer Transfer Box Equipment: Assisted Judgment of Wafer Placement Status |

Simplify control and Improve efficiency

|

Wafer Transfer Box Equipment: Assisted Judgment of Wafer Placement Status

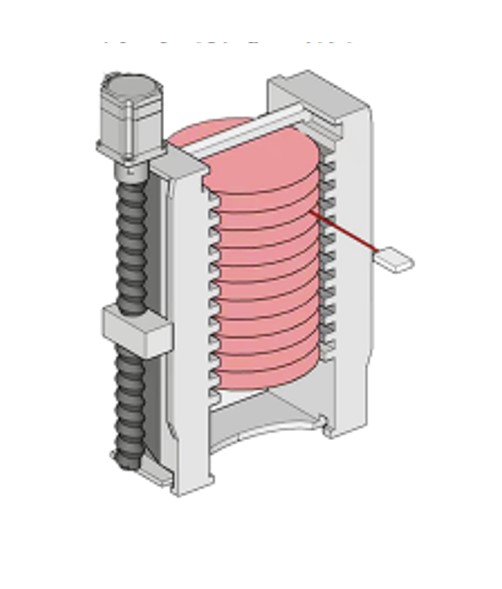

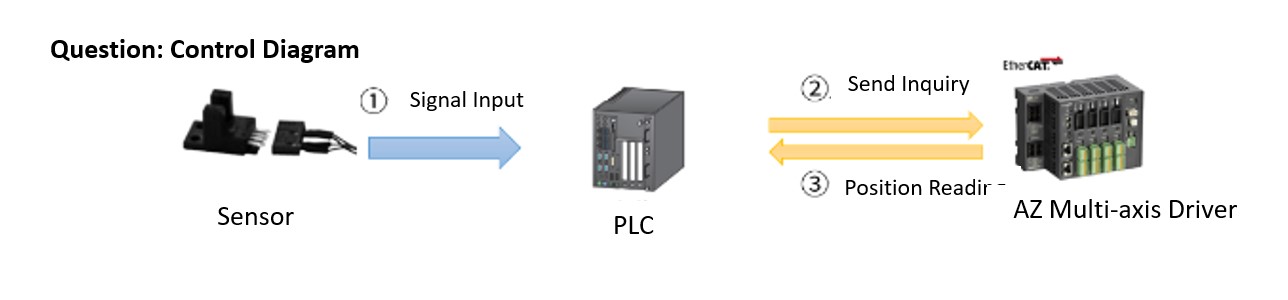

Device: Wafer Transfer BoxMechanism: Screw Mechanism Operation Condition: The screw mechanism drives the wafer to move upward and downward, during which the sensors in the box are used to assist in judging the wafer placement status, so as to facilitate the pickup operation of the next station. Issue:Previously, the control method was to connect the sensor to the PLC. Thereafter, the PLC receives the signal and send it's current positioning to the driver. river send compare the position. The PLC will then compare and judge the location of the driver This result in lags and impacts the time-efficiency. |

|

Use the probe function to read the position latch, More accurate and efficient |

|

Probe Function(Touch probe )

|

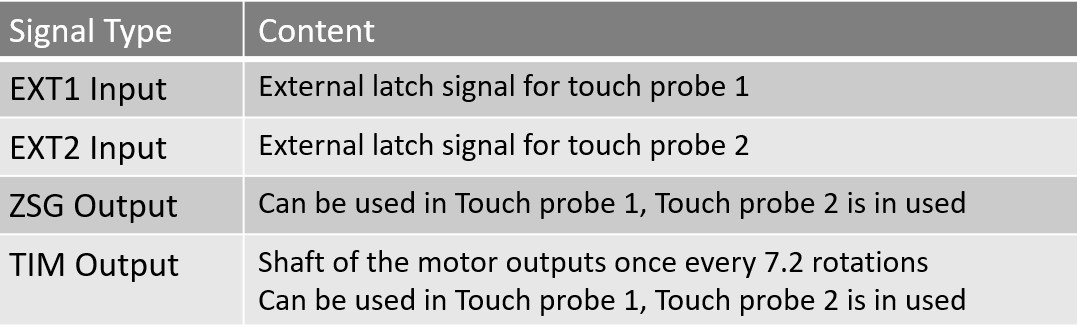

Function(Touch probe ):

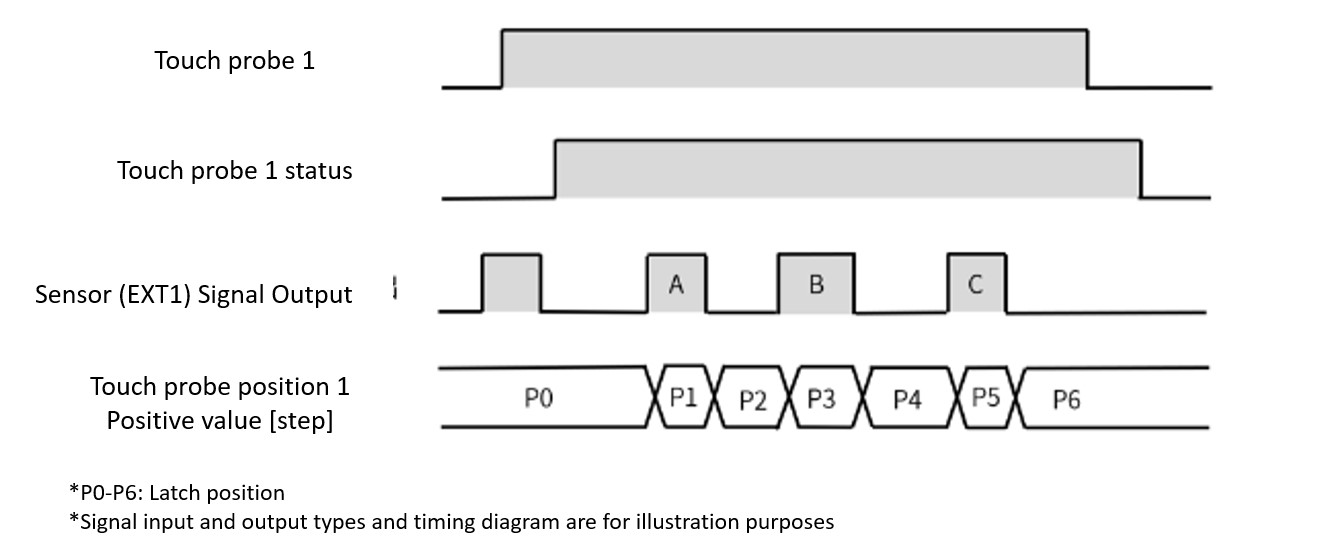

Touch probe is a function that uses an external latch input signal (EXT1 input, EXT2 input) or output signal (ZSG output, TIM output) as a trigger to latch the position of the input at the time of the trigger. |

|

External sensor signals are directly input to the driver. After the driver receives the output of the rising and falling edges of the sensor signals, it uses the Touch probe function in the AZ series EtherCAT communication to latch the position at the time of the triggering of the rising and falling edges. The upper position reads the latched position directly and periodically for application according to the processing cycle of the communication cycle.

Timing Diagram:

The PLC reads the difference between the locking position information through the rise and falling edges of the EXT1 signal through EtherCAT communication. It is then multiplied by the motor step angle to obtain the thickness of the measured wafer for auxiliary judgment and application in related production.

Example:

Thickness of A = (P2-P1) * motor step angle

Thickness of B = (P4-P3) * motor step angle

Thickness of C = (P6-P5) * motor step angle

Simplifies PLC programming, enables more efficient judgments and optimizes control programs.

Wide selection of drivers available in the AZ series that support EtherCAT communication

|

The AZ series is available in a wide range of drive types. This includes Multi-Axis, Dual-Axis, Single-Axis and Mini Drivers, to suit a wide range of applications.

|

Related Products

|

αSTEP AZ Series |