Select From Electric Actuators - Fine Tuning and Fine Feeding

You can choose from a series of electric actuators with a motor attached to mechanical components. Ready-to-use without the need for installation, adjustment, or inspection.

Compact electric cylinders that integrate a motor with ball screw for linear motion are available.

The effect of backlash due to rigidity and component combinations is minimized to achieve high-precision positioning that contributes to fine tuning and fine feeding.

DRS2/DR Series equipped with battery-free absolute encoder and capable of push-motion operation, and

DRL II Series that achieves low vibration operation and can be combined with CVD driver for 5-phase stepper motor are available.

Battery-Free Built-In Absolute Encoder

DR Series (frame size: 20 mm, 28 mm)Click here for details

DRS2 Series (frame size 42 mm, 60 mm)Click here for details

| Series Name | Frame Size (mm) |

Ball Screw Type |

Accuracy | Stroke (mm) |

||

|---|---|---|---|---|---|---|

| Repetitive positioning accuracy (mm) |

Type | Lost Motion (mm) |

||||

DR Series

|

20 | Precision | ±0.003 | Table type | 0.02 max. | 25 |

| Rod type | ||||||

| 28 | Rolled | ±0.01 | Table type | 0.05 max. | 30 | |

| Precision | ±0.003 [±0.005]* |

0.02 max. | ||||

| Rolled | ±0.01 | Rod type | 0.05 max. | |||

| Precision | ±0.003 | 0.02 max. | ||||

DRS2 Series

|

42 | Rolled | ±0.01 [±0.02]* |

Guide type | 0.05 max. | 40 |

| Precision | ±0.003 [±0.005]* |

0.02 max. | ||||

| Rolled | ±0.01 | Non-guide type | 0.05 max. | |||

| Precision | ±0.003 | 0.02 max. | ||||

| 60 | Rolled | ±0.01 | Non-guide type | 0.05 max. | 50 | |

- Specifications will vary according to conditions. For details, check the specifications for each product.

Can be Combined With CVD Driver

DRL II SeriesClick here for details

| Series Name | Frame Size (mm) |

Ball Screw Type |

Accuracy | Stroke (mm) |

||

|---|---|---|---|---|---|---|

| Repetitive positioning accuracy (mm) |

Type | Lost Motion (mm) |

||||

DRL II Series

|

20 | Precision | ±0.003 [±0.01]* |

Guide type | 0.02 max. | 25 |

| ±0.003 | Non-guide type | |||||

| 28 | Rolled | ±0.01 | Guide type | 0.05 max. | 30 | |

| Non-guide type | ||||||

| Precision | ±0.003 [±0.01]* |

Guide type | 0.02 max. | |||

| ±0.003 | Non-guide type | |||||

| 42 | Precision | ±0.01 | Guide type | 0.05 max. | 40 | |

| Non-guide type | ||||||

| Rolled | ±0.003 [±0.01]* |

Guide type | 0.02 max. | |||

| ±0.003 | Non-guide type | 0.02 max. | ||||

| Precision | ±0.01 | Guide type | 0.05 max. | |||

| Non-guide type | ||||||

| 60 | Rolled | ±0.01 | Guide type | 0.05 max. | 50 | |

| Non-guide type | ||||||

| Precision | ±0.003 [±0.01]* |

Guide type | 0.02 max. | |||

| ±0.003 | Non-guide type | |||||

- Specifications will vary according to conditions. For details, check the specifications for each product.

Application Examples

We introduce examples of equipment that we have manufactured in-house and specific solution examples for equipment challenges. Based on these, we provide easy-to-understand illustrations and videos on how to choose and utilize our products.

Click here for details

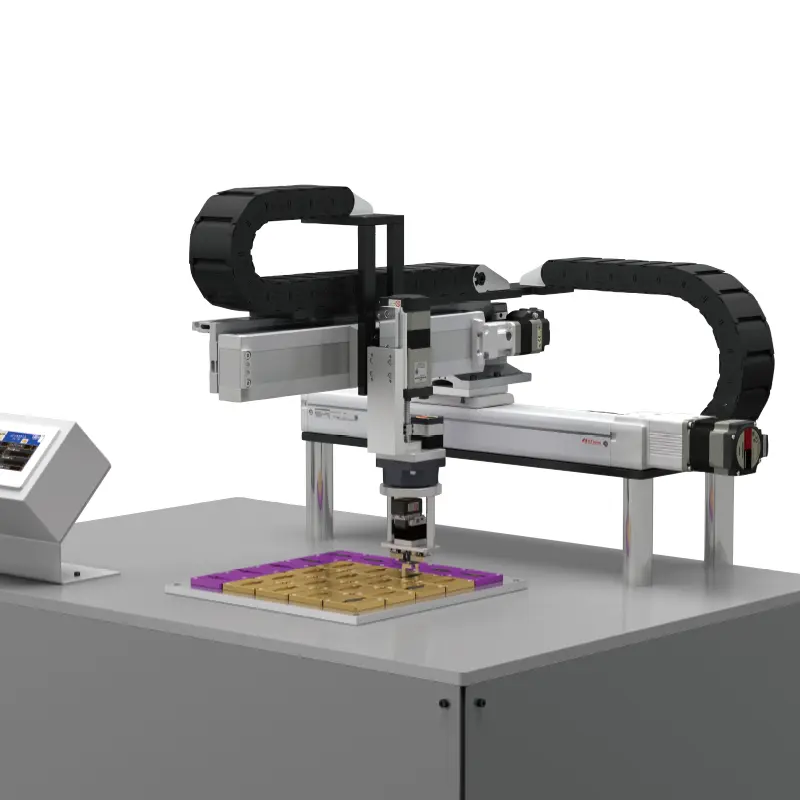

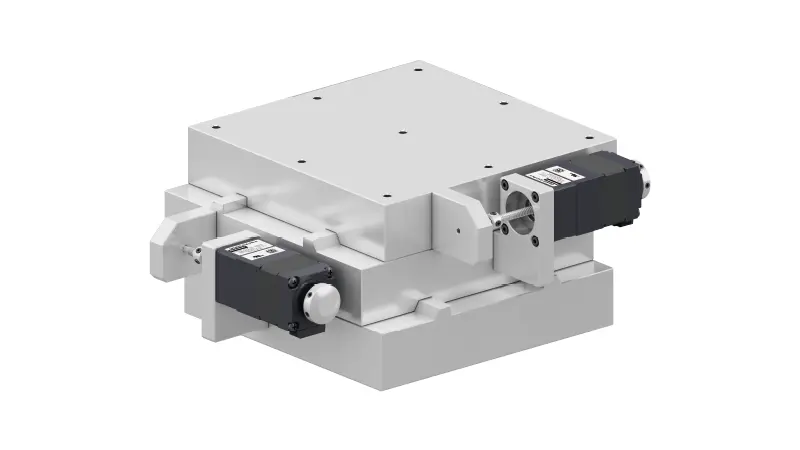

Driving an XY Stage (Automated micrometer head)

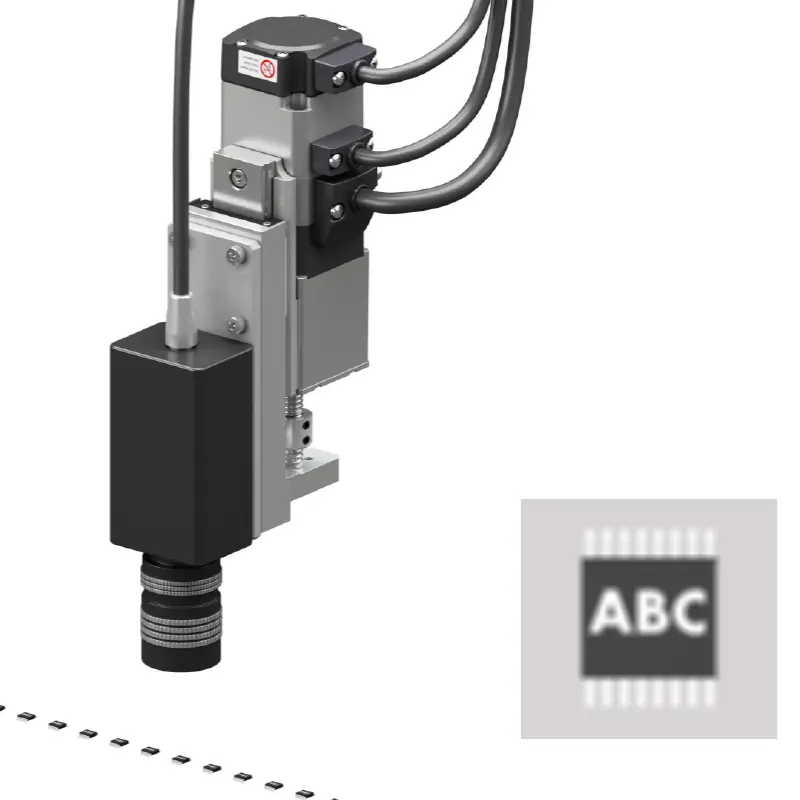

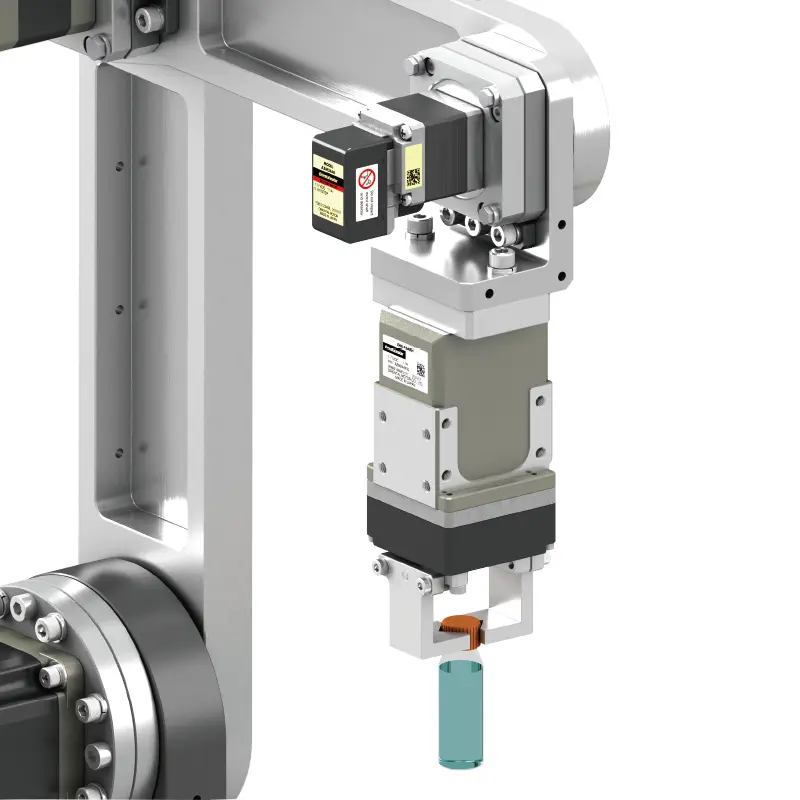

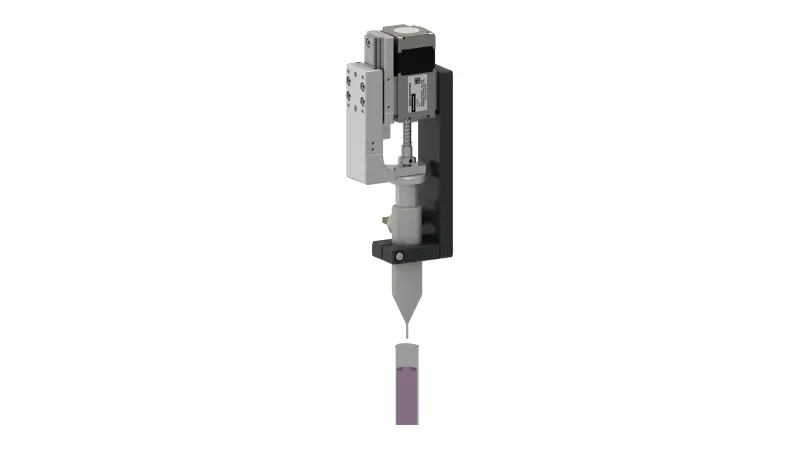

Dispenser (Pouring equipment)

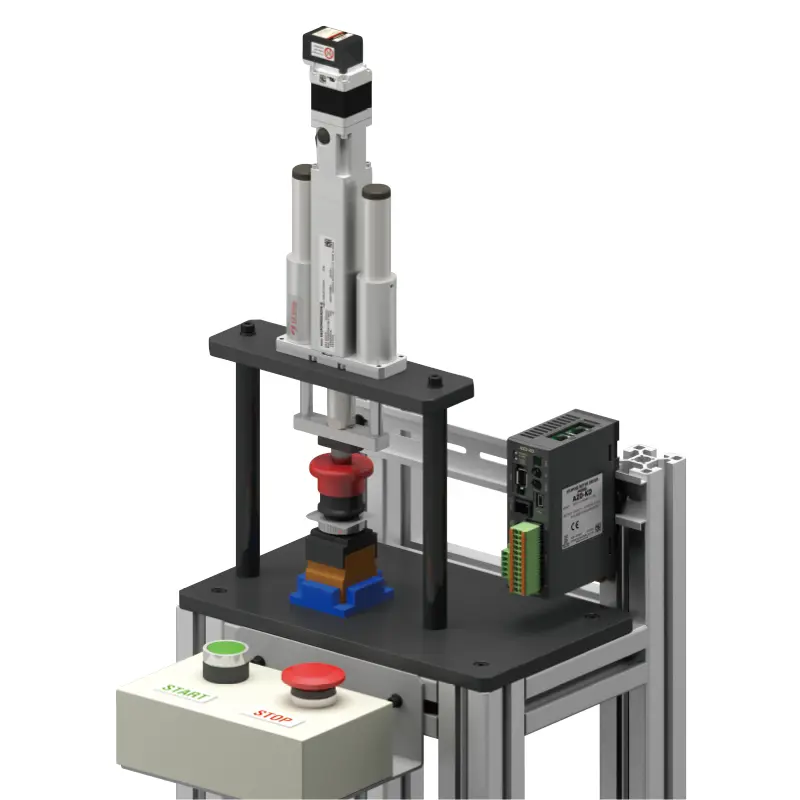

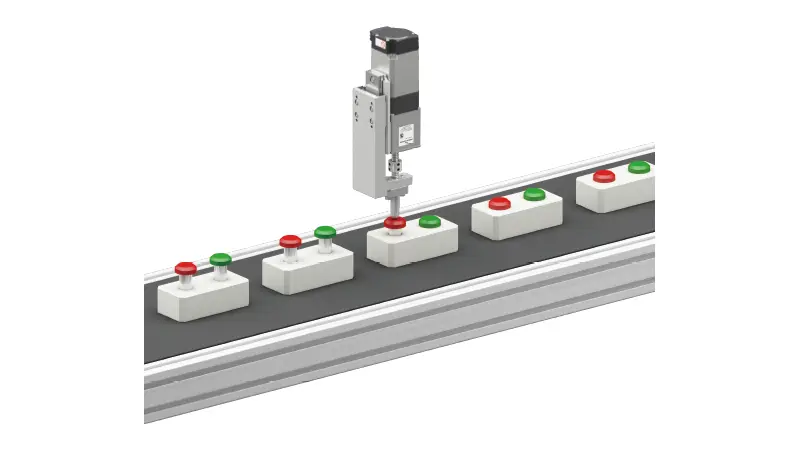

Press Fit Pins

Design Support

Contributes to "reducing equipment start-up time" for customers.

Usage Navigation

This section explains usage examples using simple sequences and various functions of the AZ Series/AZ Series-equipped actuators. More specific and practical applications will be explained in an easy-to-understand, and detailed manner.

Click here for details

Sample CAD Data

Sample CAD data of the peripheral plates that are used for mounting electric actuators can be downloaded from this website. We hope you find this information useful in designing equipment and considering products.

Click here for details