Equipped with Built-in Battery-Free Absolute Encoder

αSTEP AZ Series mini Driver

DC Input

- Compact and Lightweight with DC Input

- Compatible with Battery Power

- Industrial Network Compatible

Features | αSTEP AZ Series mini Driver

Compact Design to Fit in Small Spaces/Lightweight Design Reduces Equipment Burden

| Single Axis Driver Network Compatible* | mini Driver Network Compatible* |

|---|---|

|

🡇63 % Reduction in Size |

|

|

| W 45 mm × D 70 mm × H 100 mm | W 69 mm × D 56 mm × H 30 mm |

| Mass: 180 g | Mass: 110 g |

- *Dimensions and mass are the same regardless of network type.

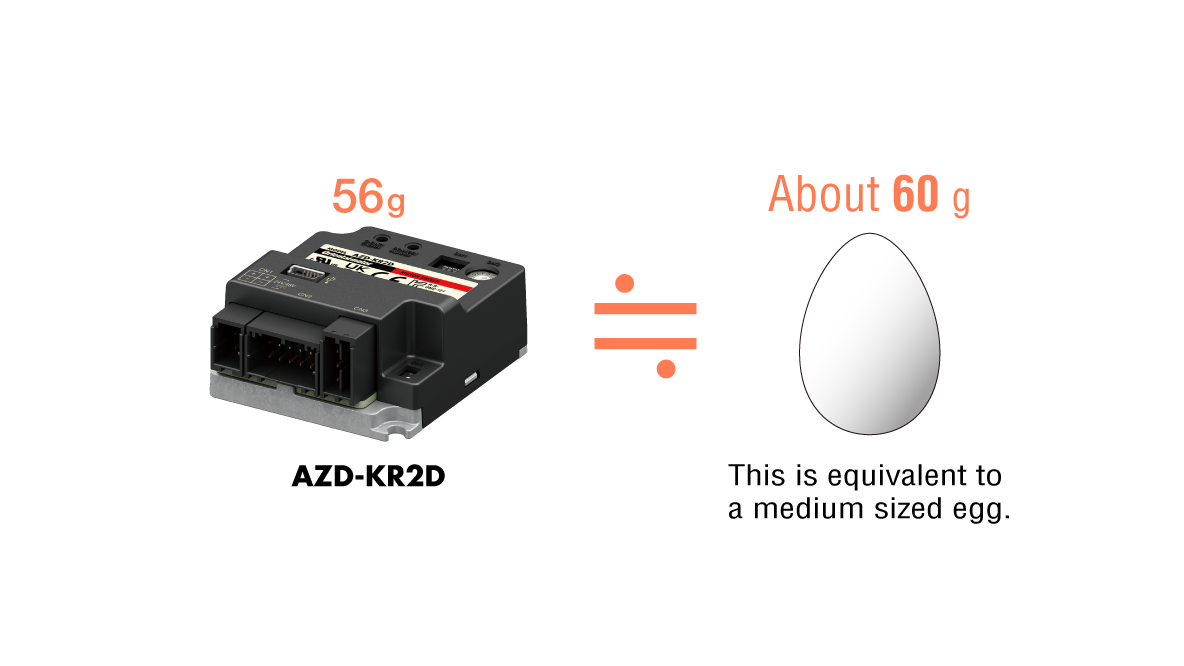

| Single Axis Driver (Built-in controller type) | mini driver RS-485 Communication Type |

|---|---|

|

🡇75 % Reduction in Size |

|

|

| W 35 mm × D 70 mm × H 100 mm | W 47 mm × D 53 mm × H 24 mm |

| Mass: 150 g | Mass: 56 g |

| Single Axis Driver Pulse Input Type With RS-485 Communication | mini Driver Pulse Input Type With RS-485 Communication |

|---|---|

|

🡇60 % Reduction in Size |

|

|

| W 35 mm × D 70 mm × H 100 mm | W 69 mm × D 56 mm × H 25 mm |

| Mass: 150 g | Mass: 84 g |

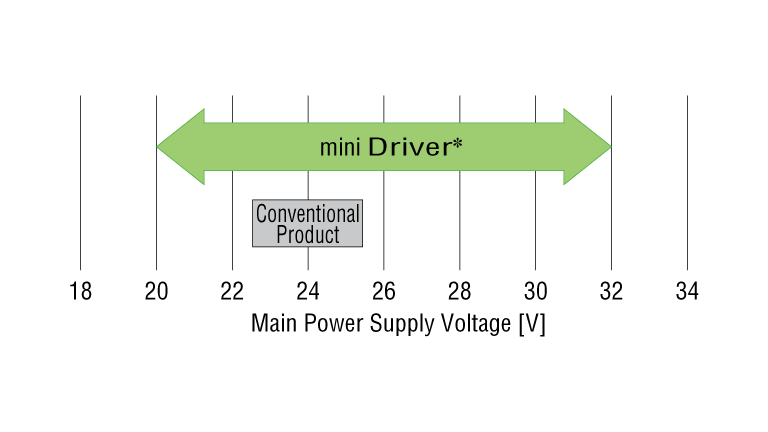

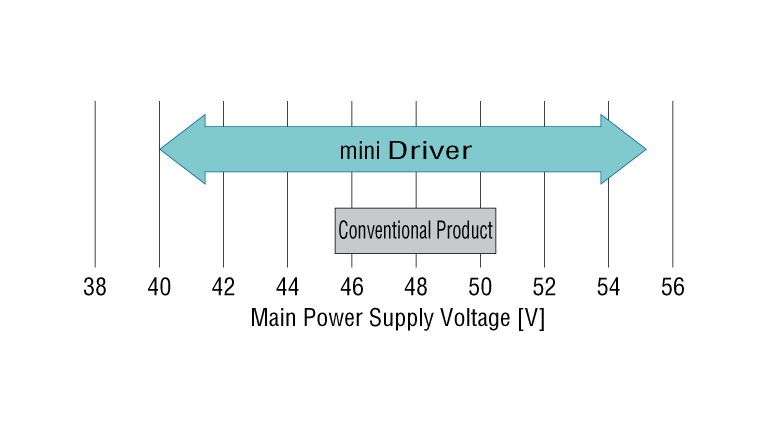

Compatible With Battery Power

A wide range of power supply voltage specifications are available for use with battery power supply. 24 VDC and 48 VDC are supported. The following shows the range of allowable operating voltages.

-

When used with 24 VDC

- *For electromagnetic brake motors, the voltage range is 22.8 to 32 VDC.

-

When Used With 48 VDC

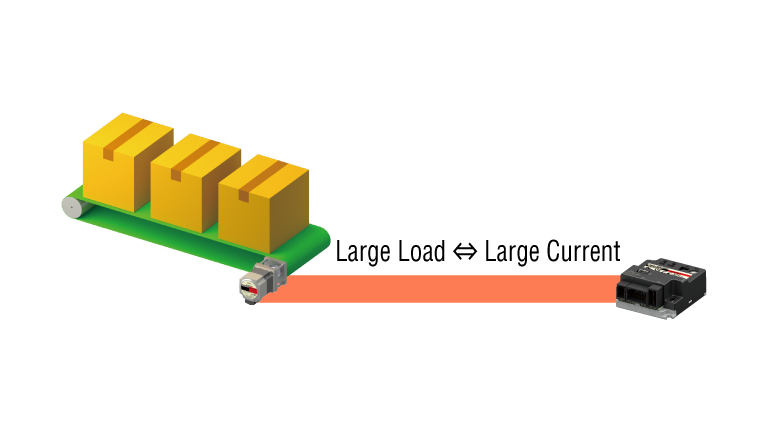

Optimal Current Control Saves Energy

The servo emulation mode optimizes the current supplied to the motor according to the load conditions.

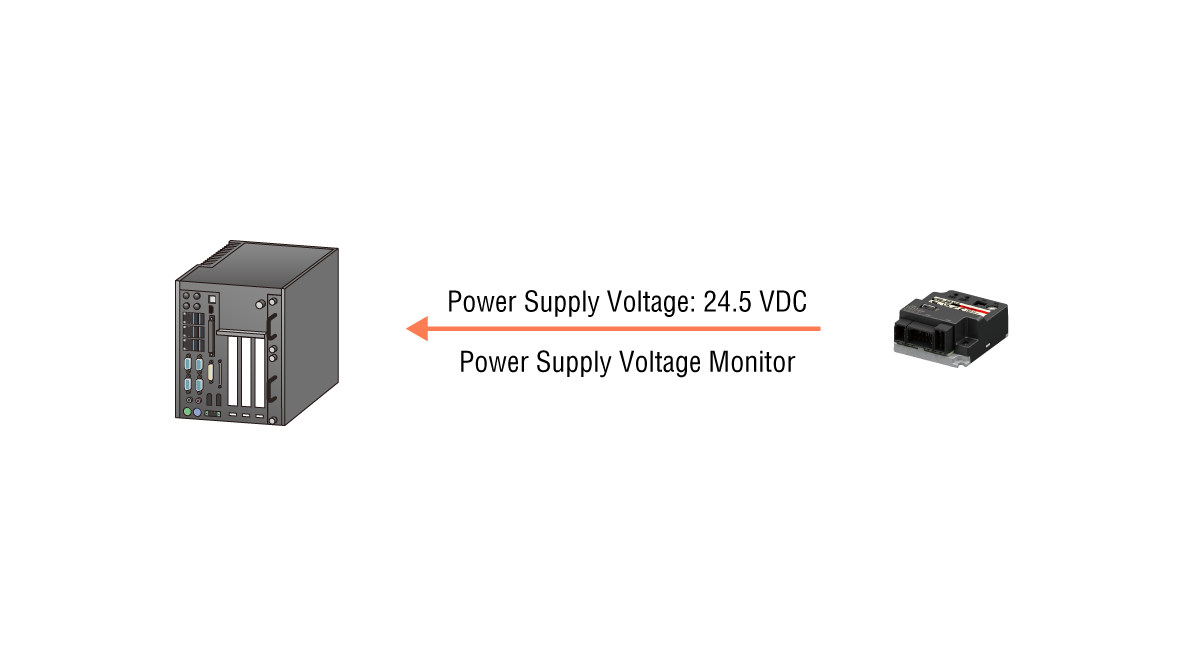

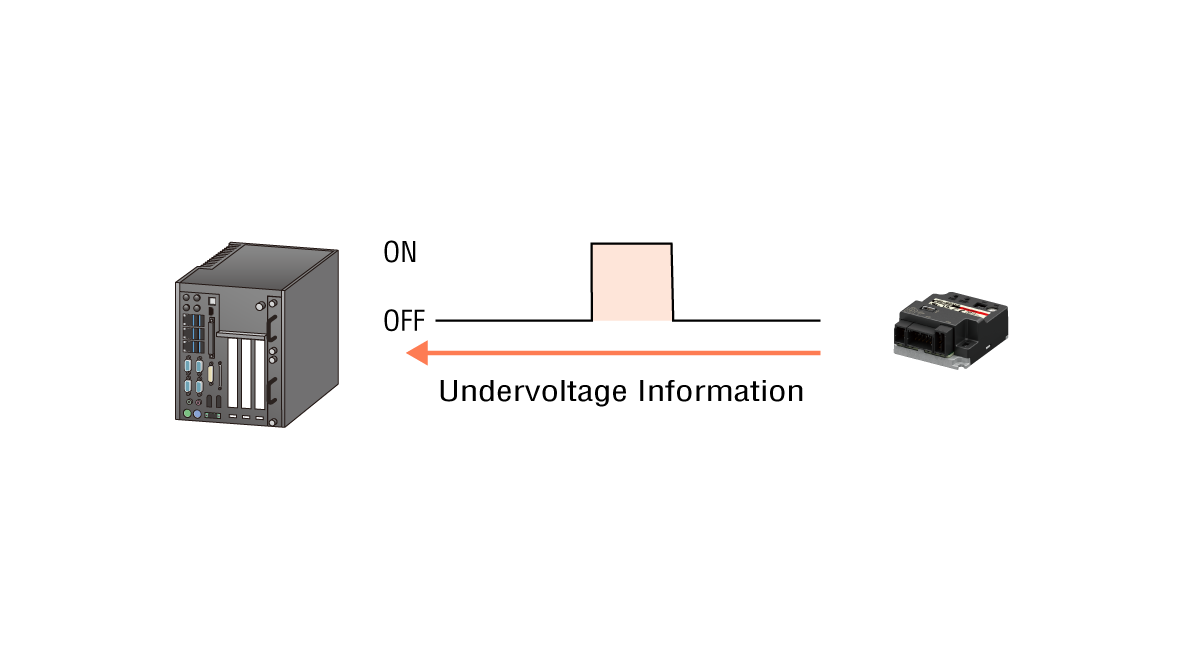

Visualization of Power Supply Voltage

-

The power supply voltage of the driver can be monitored from a host control device.

-

If the driver power supply voltage drops below a pre-set threshold, a signal is output.

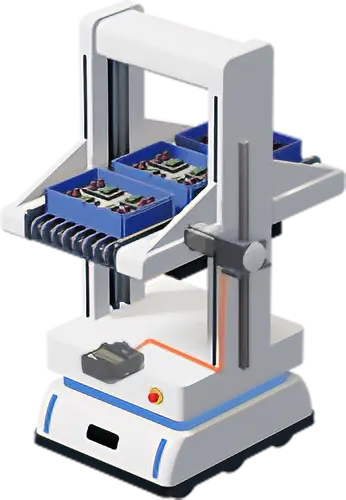

Applications

Incorporation Into Self-Propelled Devices

| Equipment Problem | Battery operation time must be maximized. |

|---|---|

| Solution With mini Driver |

|

Lightweight Design Reduces Equipment Burden

By reducing the overall equipment mass, the power consumption for the wheel drive shafts can be reduced.

- *The mass is 84~110 g except for AZD-KR2D.

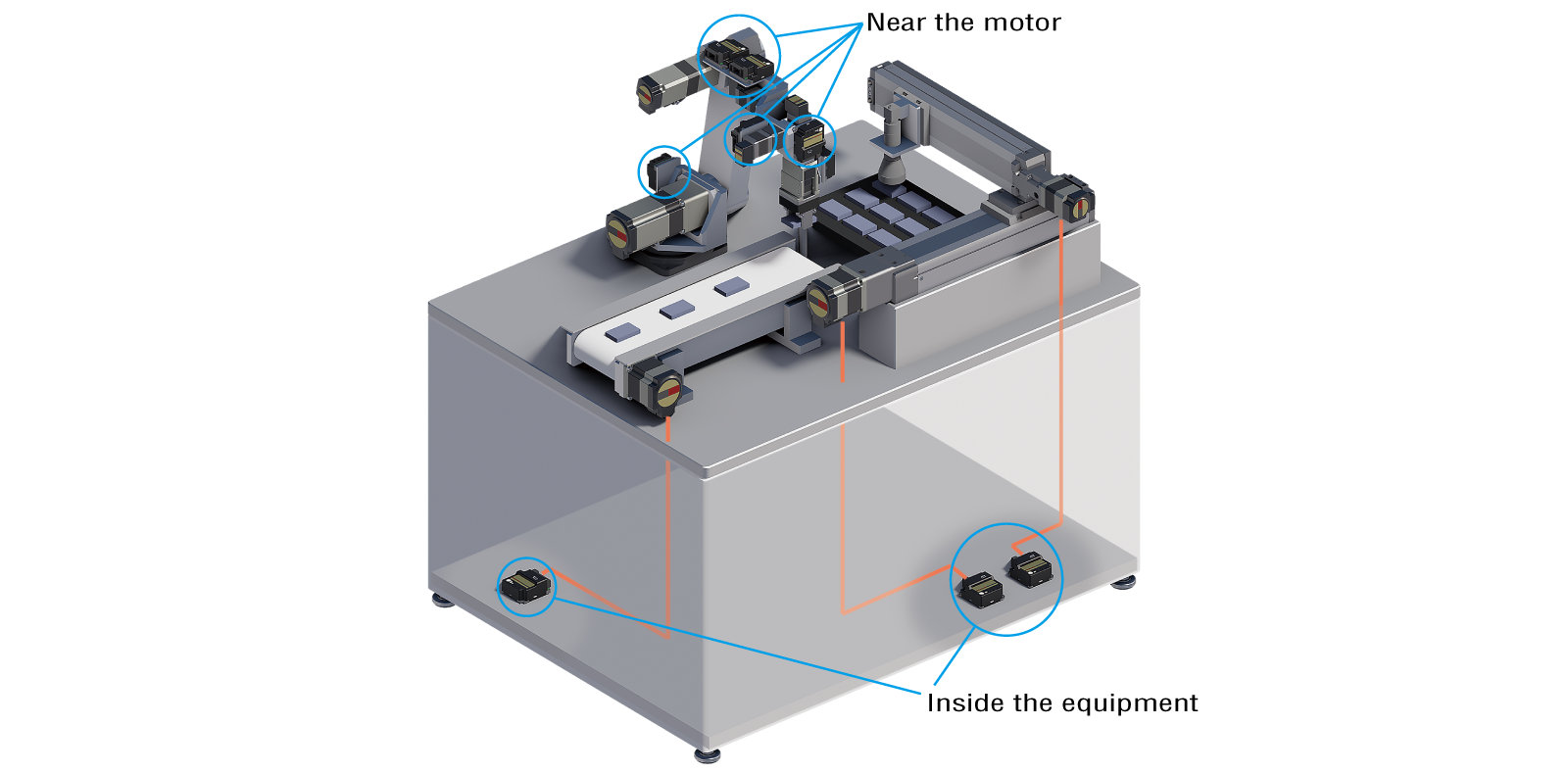

Incorporation into Stationary Equipment

| Equipment Problem | Install the driver and control systems in separate locations to reduce overall equipment size. |

|---|---|

| Solution With mini Driver |

|

Mounting Brackets Are Available to Enable Space-Saving and Wiring-Saving Installation of the Motor and Driver

- The driver can be installed on the side of the motor

- Motor and driver installed close to each other for space-saving installation

- Motor and driver can be easily connected with a single cable

Product Line

| Interface | Driver Type | Power Supply Input | |

|---|---|---|---|

|

EtherCAT compatible | 24/48 VDC | |

|

EtherNet/IPTM compatible | 24/48 VDC | |

|

PROFINET compatible | 24/48 VDC | |

|

Modbus (TCP, UDP) |

Ethernet type | 24/48 VDC |

|

Modbus (RTU) | RS-485 communication type | 24/48 VDC |

|

Pulse | Pulse input type with RS-485 communication | 24/48 VDC |

- *EtherCAT compatible products have passed the official EtherCAT conformance test.

- *The RS-485 communication type can be controlled via CC-Link or MECHATROLINK by using with the network converter (gateway) sold separately.

Narrow down Products