What are Oriental Motor’s Industrial Robots and Controllers?

This controller can control the compact industrial robot OVR with its arm combined with an αSTEP AZ Series motor and robots configured with the AZ Series, including OVR. It is also easy to set up for operation and is suitable for promoting automation in areas where regular industrial robots are too large, or the total costs are too great.

What are Oriental Motor’s Industrial Robots and Controllers?

Overview and Related Information

Concept

Simple, Small Size. The Perfect Fit.

I want a simple small robot for automation. I want to achieve automation more quickly.

Oriental Motor is expanding its products and services that respond to both the needs of in-house manufacture and purchases of simple and small industrial robots.

We help promote automation.

Robots OVR with simple mechanisms and controls that can be configured relatively inexpensively.

We have a range of compact shapes and operating mechanisms that are perfect for changing existing lines.

Easy control of the Small Robots OVR and AZ Series motor-equipped mechanisms. Operational programming and simulation are possible with commands.

Intuitive operations reduce the burden required for robot installation.

We provide selection calculations and technical seminars. We can also provide support for testing of the actual equipment, program support, on-site start-up, or any other support that is difficult for you to complete yourself.

Product Line

Small Robots OVR

Simple, compact, lightweight industrial robot consisting of αSTEP AZ Series motor with battery-free built-in absolute encoder.

Controlled by the intuitive robot controller MRC01, automation using multi-axis robots can be achieved with ease.

Some motors can be replaced by the customer, reducing maintenance costs.

- ·To drive the robot, drivers according to the number of motor axes in the robot and a robot controller MRC01 are required separately.

6-Axis Articulated Robot

Maximum Payload: 1 kg

Maximum Reach: 480 mm (horizontal)

- Approaches load from various angles

- Body mass 12.5 kg

5-Axis Articulated Robot

Maximum Payload: 1 kg

Maximum Reach: 350 mm (horizontal)

- Customizable in combination with electric linear slides

- Body mass 12.5 kg

4-Axis Articulated Robot

Maximum Payload: 5 kg

Maximum Reach (Horizontal) 3 Types: 480 mm, 680 mm, and 880 mm

- Stable transport of load in a constant horizontal state

- Body mass 16.5 kg, 17.4 kg, 26.9 kg

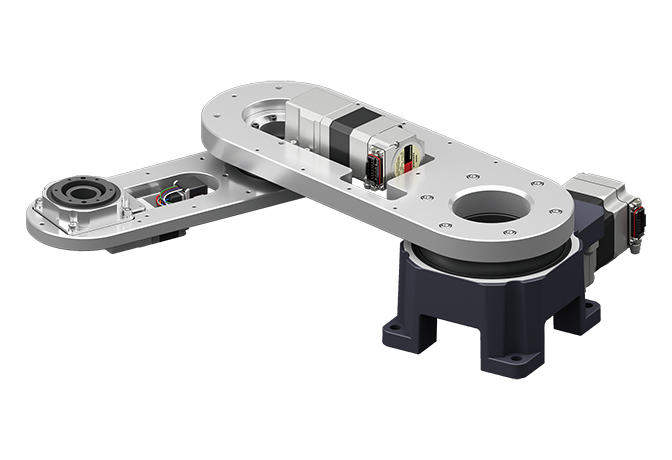

3-Axis SCARA Robot

Maximum Payload: 3 kg

Maximum Reach (Horizontal) 410 mm

- Flat SCARA that can approach narrow spaces at 140 mm in height

- Body mass 7.6 kg

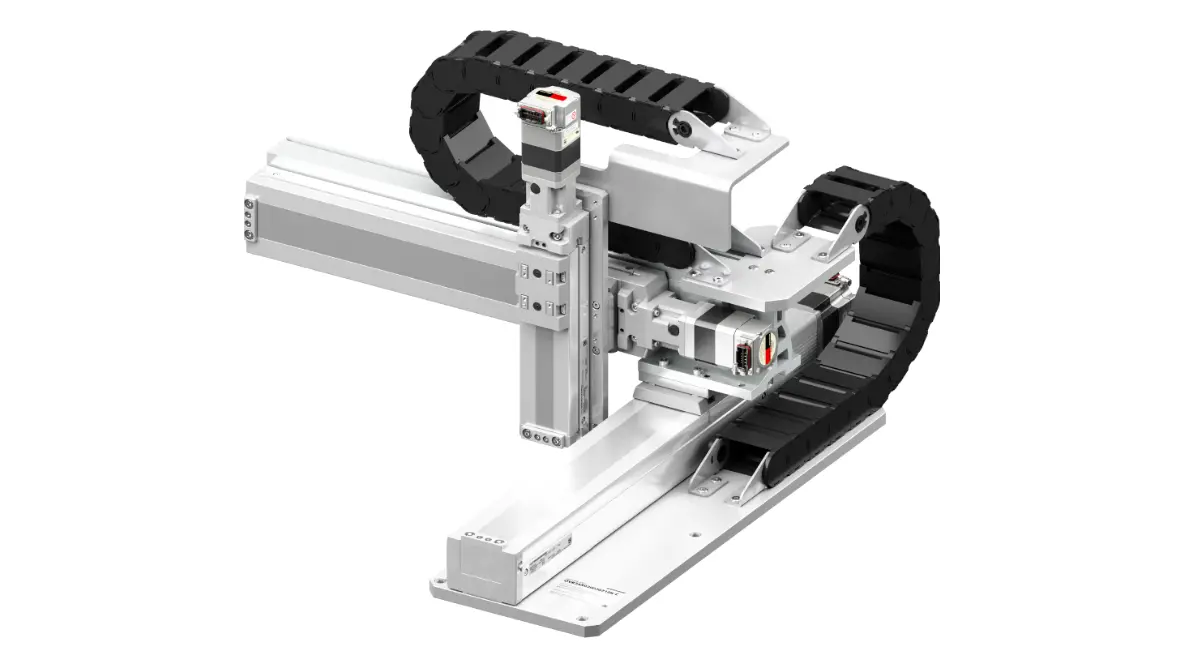

Cartesian Robot

Maximum Payload: 2.5 kg

Movable Range: 300 x 300 x 100 mm (X-Y-Z)

- Delivering the electric linear slide EZS Series pre-assembled with three axes

- Body mass 18.4 kg

Robot Controller

Controller capable of controlling Small Robots OVR or multi-axis devices composed of the αSTEP AZ Series.

Setup is simply a matter of following the wizard in the MRC Studio control software (free). Operations such as PTP, arch interpolation, circular interpolation, and palletizing can be intuitively set using command icons, allowing for a smooth introduction even for those who have never created a robot program before. There is a lower barrier to entry for automation.

Supported Robot Types: SCARA, articulated, palletizer, cartesian, delta robot, polar robot/cylindrical robot

Robot Controller

MRC01-C

- Dedicated, low-cost controller for cartesian robots

Click Here for a List of Robot and Controller Products and Details

Provides Various Types of Support for Considering and Using Robots

We support customers to rapidly achieve automation by eliminating concerns such as “is it really usable?” and “how difficult is it?”.

Some support will be provided for a fee in cooperation with ORIMVEXTA CO., LTD. (our affiliate company). Enjoy one-stop support you need, regardless of the point of purchase. Please contact Oriental Motor for details.

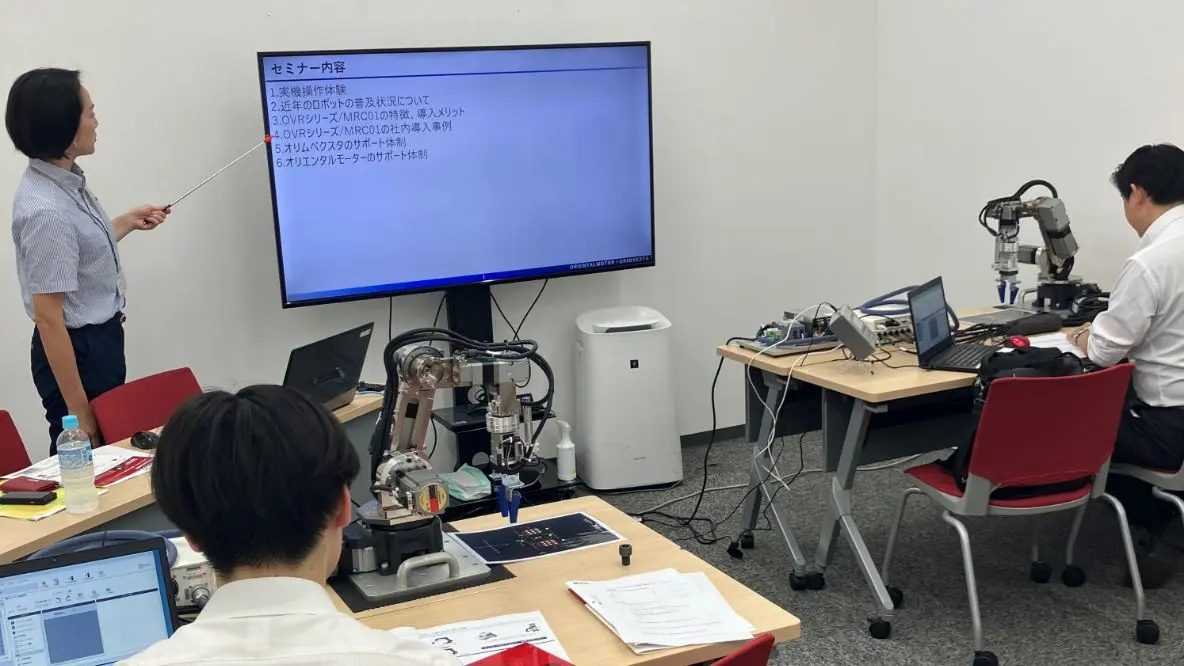

Hands-On Seminars on Robot Control [Regularly scheduled]

The benefits of introducing robots and the MRC01 will be explained through the operation of a demonstration unit with the robot controller MRC01 and the dedicated PC software MRC Studio.

- Automation of processes to save manpower and improve efficiency

- Proposed solutions using the MRC01 robot controller

- Robot motion simulation using MRC Studio Simulator

- The first step to bringing in robots! Industrial Robot Hands-On Seminar to Get Started at Your Company: Programming Basics

Load Test and Real Equipment Rental Service

By operating the actual equipment in our environment with real loads, you will be able to see whether or not the gripping is possible and whether or the transportation speed for certain weights is satisfactory.

We will also loan you the equipment so that you can check explore within your own environment.

On-Site and Remote Demonstrations

We will bring the robot to the customer site for an on-site demonstration to see the robot in action directly, or conduct a remote demonstration to introduce the robot's operation through an online webinar. Use it at you best see fit.

Simulation Software

We offer PC software that allows for simulations of actual movements without the robot itself or MRC01, as well as iPhone and iPad apps that enable AR-based simulations of the robot's installation and operation.

Start-Up and Programming Support

Supports connection and configuration of the robot controller MRC01 and the robot. We also provide a program for basic operation of the robot controller via Ethernet/IP communication. If you are unsure when using the communication control for the first time, we offer support, including the linkage with the programming software MRC Studio.

Inspection and Repair Services

When a problem occurs, our service engineers will visit the site, or help via phone or video conference, to assess the situation, and will take the product back to the customer for inspection and repair.

Please feel free to contact us for information not included in the catalog, purchasing information, or support details.