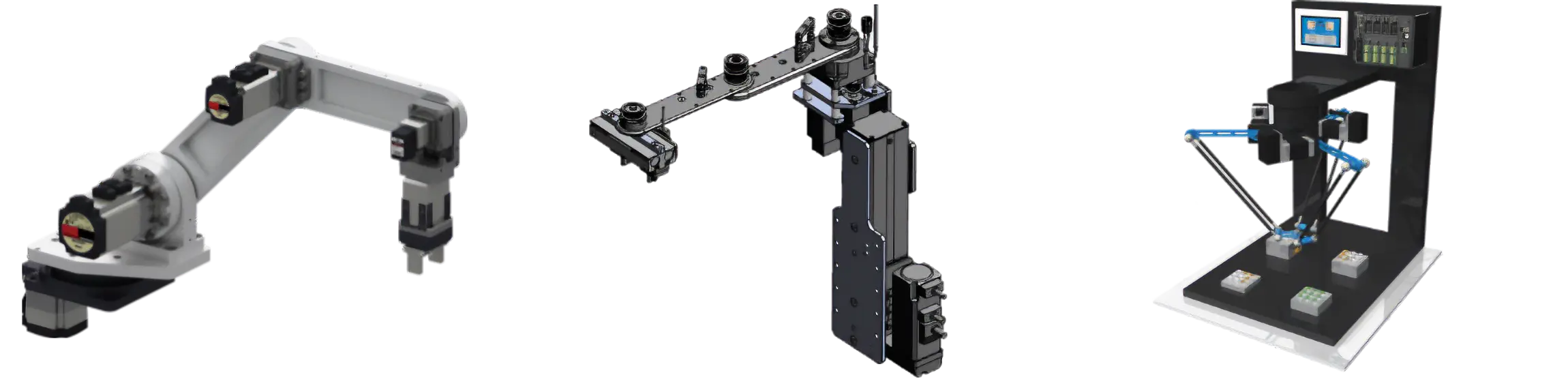

Extensive Support for In-House Production and Introduction of Robots

When deploying a robot, do you have design concerns or misgivings such as "I want to manufacture the robot in-house," "Commercial products are functionally over-engineered," or "I don't know how to select a motor for in-house production?"

In this page, Oriental Motor introduces the key points based on a demonstration unit actually produced by Oriental Motor.

In addition, related services for customers who are considering in-house production of robots will be introduced.

Please feel free to contact us if you have any questions.

Articulated Robot Demonstration Unit

Demonstration Unit Overview

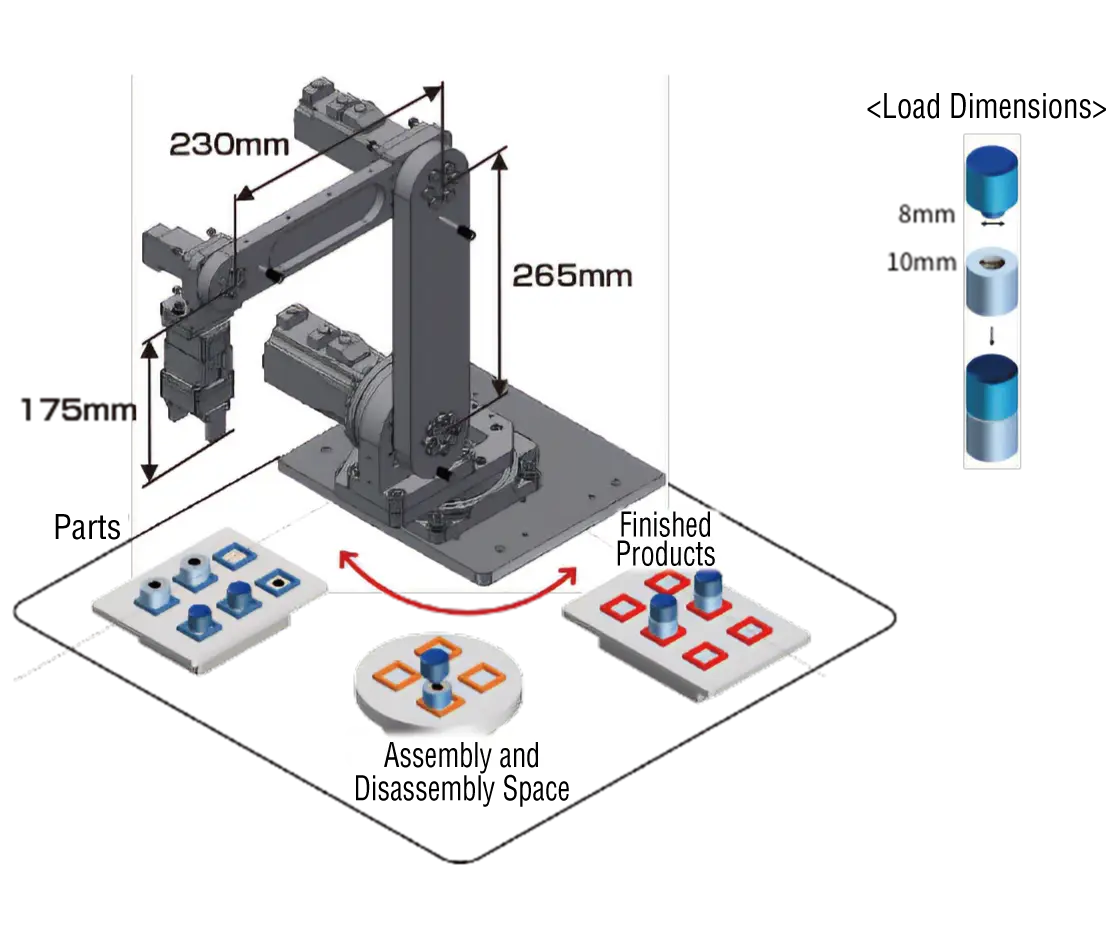

This is a demonstration unit for an articulated robot that mimics the parts assembly process.

Pick and place the 2 parts in the assembly space, assemble them, and transfer the finished product to the completion space.

| Number of axes | 5-axis |

|---|---|

| Installation Method | Floor-mounted |

| Arm Length | 653 mm |

| Load Mass | 300 g |

| Main Power Supply | 100 VAC* |

| Mass | 30 kg |

- *The power supply for driving and controlling the driver is 24 VDC.

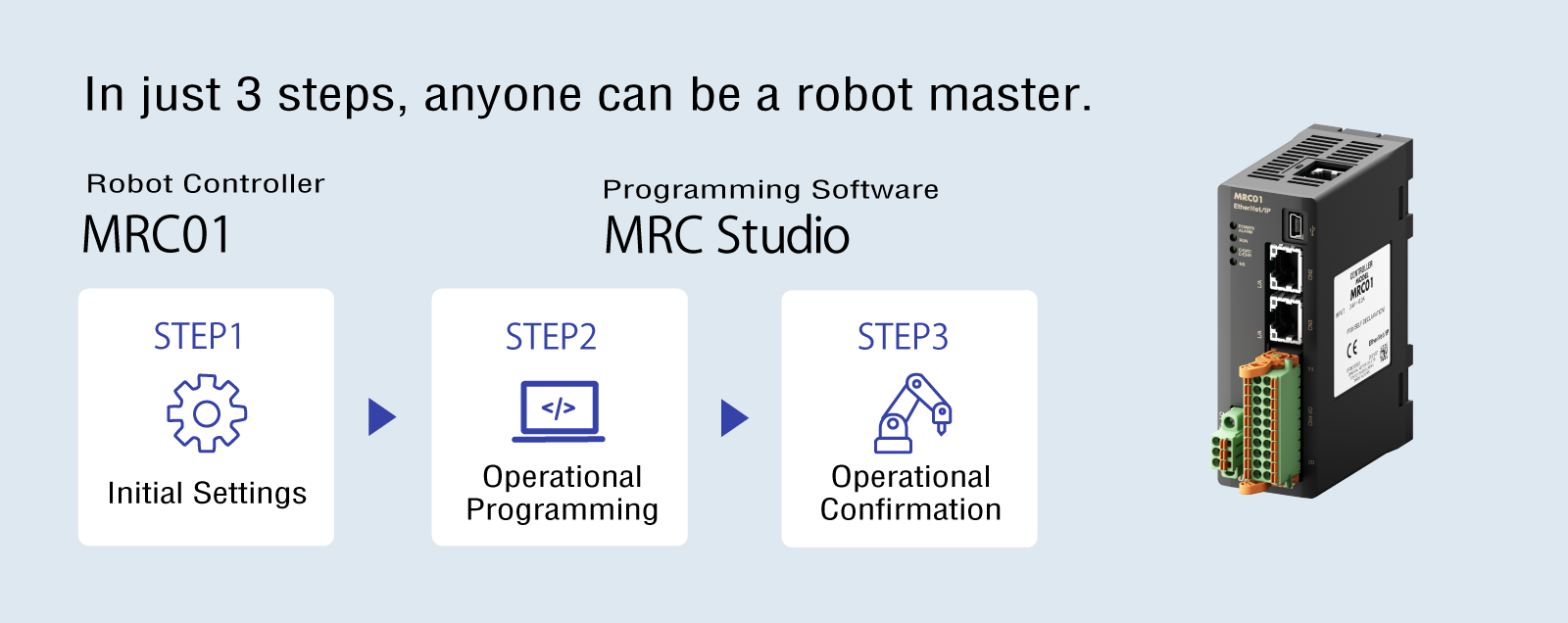

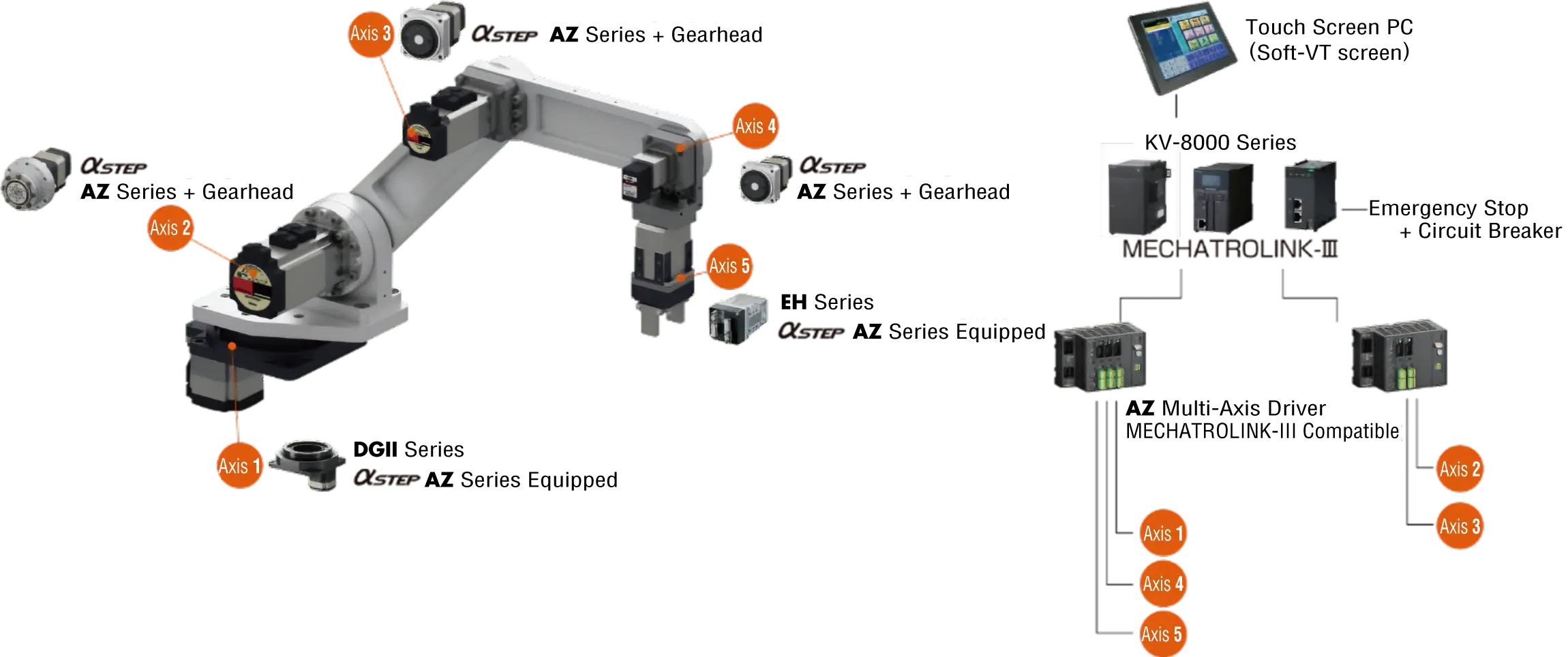

System Configuration

Each axis is controlled synchronously by MECHATROLINK-III.

Coordinates are specified using the function block of the PLC.

You can easily build your own robot with the AZ Series,

and robot controllers that can be configured and programmed are also available.

- *The MRC01 is not used in this demonstration unit.

List of Components

Motors and Electric Actuators

| Axis | Product Name | List Price (SGD) | List Price (USD) | |

|---|---|---|---|---|

|

Axis 1

|

Hollow Rotary Actuator | DGM130R-AZAK | SGD 2,406 | USD 1,925 |

| Flexible connection cable*1 | CC020VZRA | SGD 109 | USD 87 | |

|

Axis 2

|

Motor | AZM66MK | SGD 688 | USD 550 |

| Gearhead |

CSG-20-100-2UH-LW-SP-B

|

*3 | *3 | |

| Flexible Connection Cable Set For the electromagnetic brake motor only*2 |

CC030VZRBA | SGD 166 | USD 133 | |

|

Axis 3

|

Motor | AZM46MK | SGD 566 | USD 453 |

| Gearhead |

CSF-11-100-2UP-SP-C

|

*3 | *3 | |

| Flexible Connection Cable Set For the electromagnetic brake motor only*2 |

CC030VZRBA | SGD 166 | USD 133 | |

|

Axis 4 |

Motor | AZM24AK | SGD 344 | USD 275 |

| Gearhead |

CCSF-8-100-2UP-SP-A

|

*3 | *3 | |

| Flexible connection cable*2 | CC030VZ2RA | SGD 121 | USD 97 | |

|

Axis 5

|

Electric Gripper | EH4-AZAKH | SGD 908 | USD 726 |

| Flexible connection cable*1 | CC030VZ2RA | SGD 121 | USD 97 | |

- *1

- The length is 2 m.

- *2

- The length is 3 m.

- *3

- Please contact Oriental Motor for details.

Driver

| Axis | Product Name | List Price (SGD) | List Price (USD) | ||

|---|---|---|---|---|---|

|

Axis 1 Axis 4 Axis5 |

|

Multi-Axis Driver Number of Axes: 3 | AZD3A-KM3 | SGD 1,458 | USD 1,166 |

| Main Power Supply Cables | LC03D06A | SGD 20 | USD 16 | ||

| Control Power Supply Cables | LC02D06A | SGD 18 | USD 14 | ||

|

Axis2 Axis3 |

|

Multi-axis driver number of axes: 2 | AZD2A-KM3 | SGD 1,100 | USD 880 |

| Main Power Supply Cables | LC03D06A | SGD 20 | USD 16 | ||

| Control Power Supply Cables | LC02D06A | SGD 18 | USD 14 | ||

- ※

is a registered trademark of Harmonic Drive Systems Inc.

is a registered trademark of Harmonic Drive Systems Inc. - ※

MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

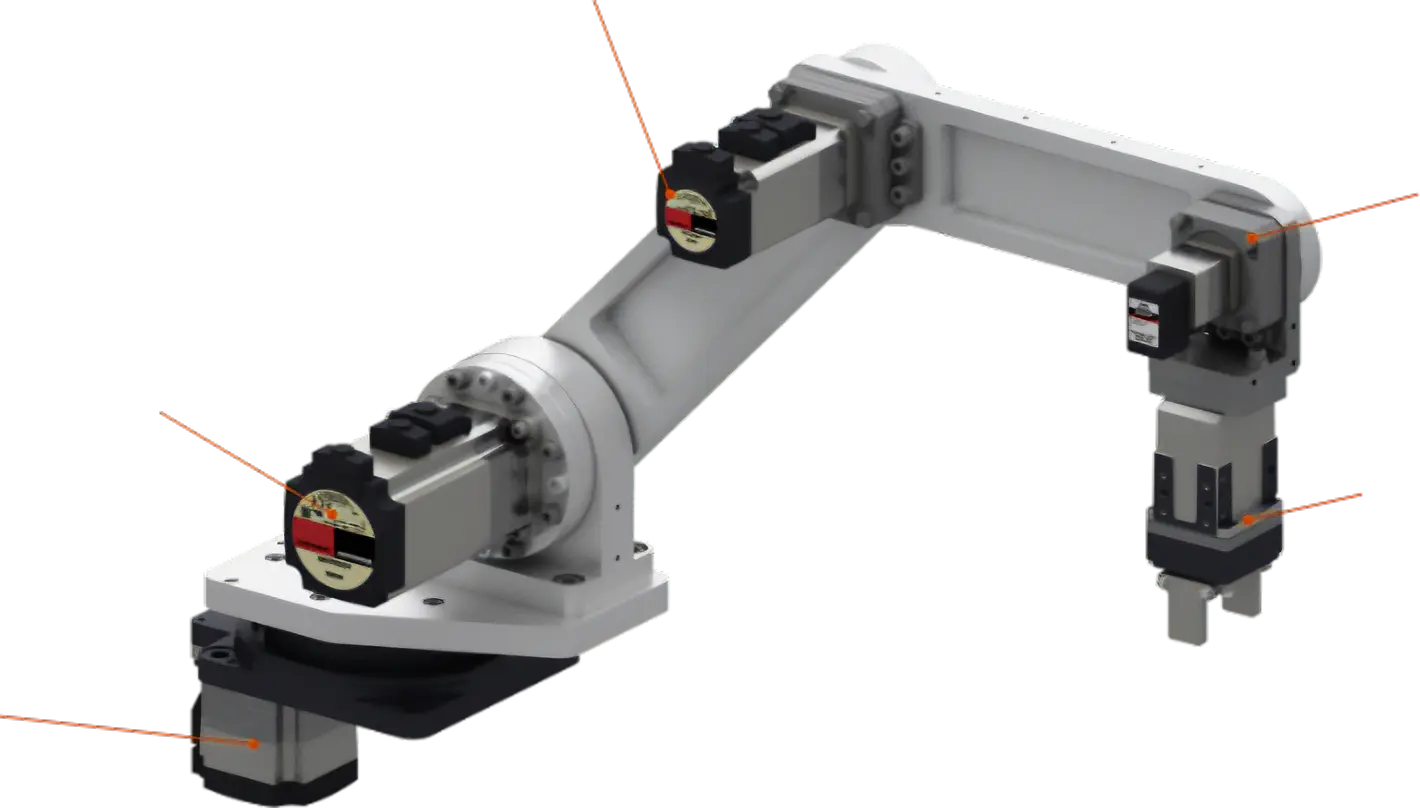

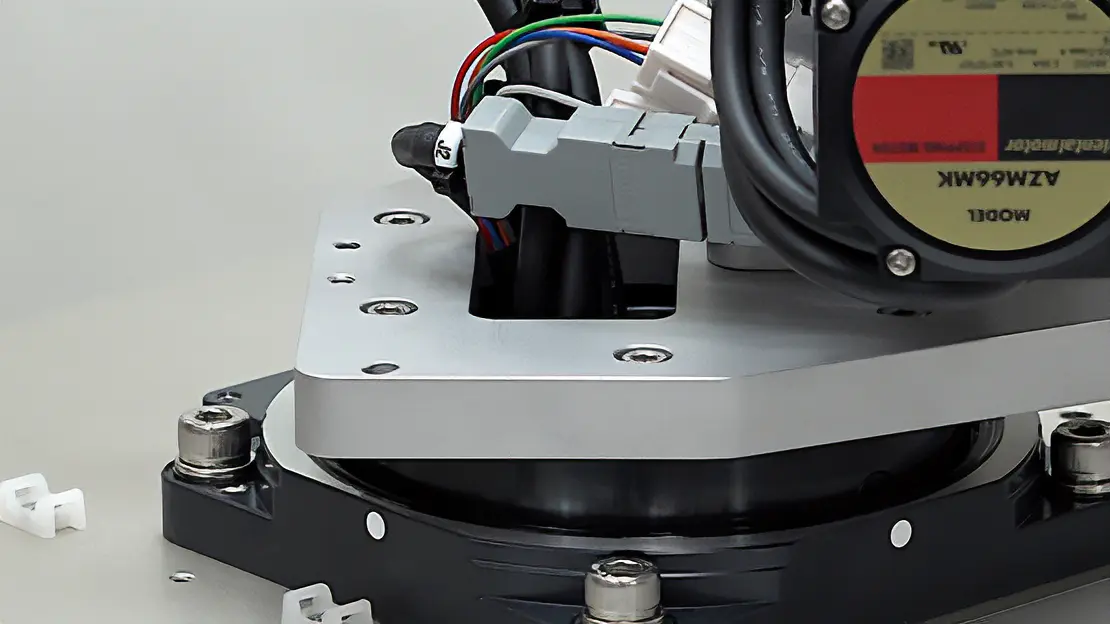

Axis ① - Arm swivel axis

<High Load Capacity and Rigidity> Hollow Rotary Actuator DGII series

To withstand increased load moments due to various arm postures,

uses high load and high rigidity table

Articulated robots generate a large load moment when gripping a workpiece that is far from the axis ①.

The DGII Series uses crossed roller bearings for the hollow output table to achieve a high permissible moment.

This allows the arm to be extended longer, contributing to an increased range of motion for the robot.

Click Here for Specific Examples of the High Rigidity

Simplify Power Cable Wiring

The power cables inside the robot are integrated into the base of the arm. The large diameter hollow hole (through-hole) realizes the complexity of wiring and piping, thus simplifying equipment design.

On-Board Equipment

Hollow Rotary Actuator

DGII Series

This is an integrated product of the hollow rotary table and αSTEP. High output power drive is possible due to the speed reduction mechanism inside the actuator.

Axis ② - Joint axis

[Lightweight, High Rigidity, Non-Backlash]

Gearheads CSG Series Package Type Light-Weight Model

Suppresses Arm Tip Misalignment for High-Precision Movement

Even a small misalignment at a joint close to axis ① may become large at the end of the arm, making it impossible to grasp the load accurately.

The CSG Series uses non-backlash gearheads to minimize misalignment and ensure accurate operation.

![[Image of Backlash and Robot Tip Misalignment]](/sites/default/files/image/solutions/casestudies/applications/robotsupport/robotsupport_21_en.webp)

Lightened Joint Axis for Increased Flexibility in Design

By reducing the weight of each joint axis, inertia is reduced and the specifications (torque and rigidity) of the mechanical components can be controlled.

The CSG Series is lightweight and at the same time highly rigid, allowing for direct mounting of loads.

No fastening parts are required, making the arm lighter and contributing to greater flexibility in design.

On-Board Equipment

CSG Series Package Type Light-Weight Model

For details, please contact your nearest Oriental Motor sales office.

Axis ③, Axis ④ - Joint axes

[Super Flat, High Rigidity, Non-Backlash]

Gearheads CSF mini Series 2UP Type

Suppresses Arm Tip Misalignment for High-Precision Movement

Even a small misalignment at a joint close to axis ① may become large at the end of the arm, making it impossible to grasp the load accurately.

The CSF mini Series uses non-backlash gearheads to minimize misalignment and ensure accurate operation.

![[Image of Backlash and Robot Tip Misalignment]](/sites/default/files/image/solutions/casestudies/applications/robotsupport/robotsupport_32_en.webp)

Lightened Joint Axis for Increased Flexibility in Design

By reducing the weight of each joint axis, inertia is reduced and the specifications (torque and rigidity) of the mechanical components can be controlled.

The CSF mini Series is lightweight and at the same time highly rigid, allowing for direct mounting of loads.

No fastening parts are required, making the arm lighter and contributing to greater flexibility in design.

-

![[Axis ③]](/sites/default/files/image/solutions/casestudies/applications/robotsupport/robotsupport_34.webp)

[Axis ③] -

![[Axis ④]](/sites/default/files/image/solutions/casestudies/applications/robotsupport/robotsupport_35.webp)

[Axis ④]

On-Board Equipment

CSF mini Series 2UP Type

For details, please contact your nearest Oriental Motor sales office.

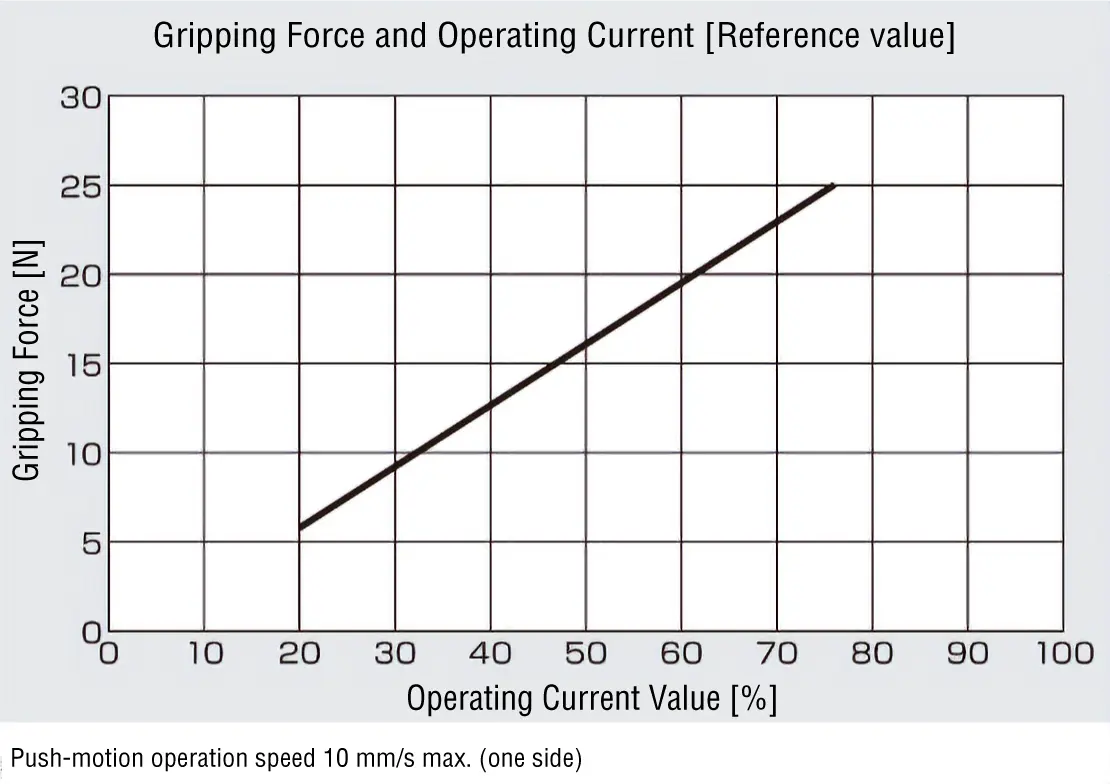

Axis ⑤ - End Effector

<Compact and lightweight> Electric Gripper EH Series

Grasp a variety of loads with a single unit

EH Series can be used for a variety of loads because the gripping force can be set freely.

(Stroke 25 mm)

Maximum gripping force 25 N

[ Gripping force range (reference value) approx. 6 N~25 N ]

![[ Example of gripping image ]](/sites/default/files/image/solutions/casestudies/applications/robotsupport/robotsupport_24_en.webp)

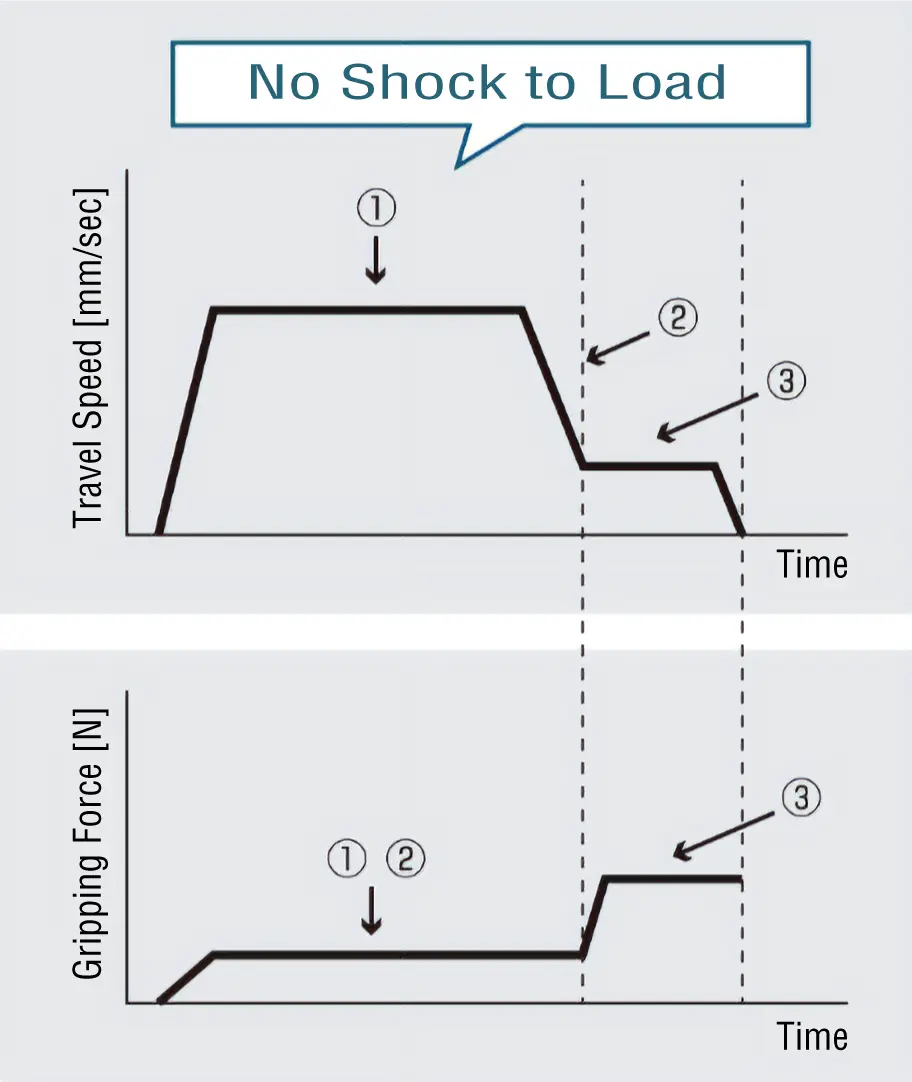

1 Unit for Various Gripping Tasks

Since it allows free setting of the clamping claw position, gripping time, and gripping force,

a variety of gripping can be achieved.

Click here for a video on gripping

Click here for examples of gripping

![[ Gripping example: Quickly until just before → Gripping slowly ]](/sites/default/files/image/solutions/casestudies/applications/robotsupport/robotsupport_25_en.webp)

On-Board Equipment

Electric Gripper EH Series αSTEP AZ Series Equipped

This electric gripper combines rack-and-pinion mechanisms with the αSTEP AZ Series. It achieves a delicate "grasp" like human fingertips, and assists in automation and labor saving.

Common to All Axes

αSTEP AZ Series

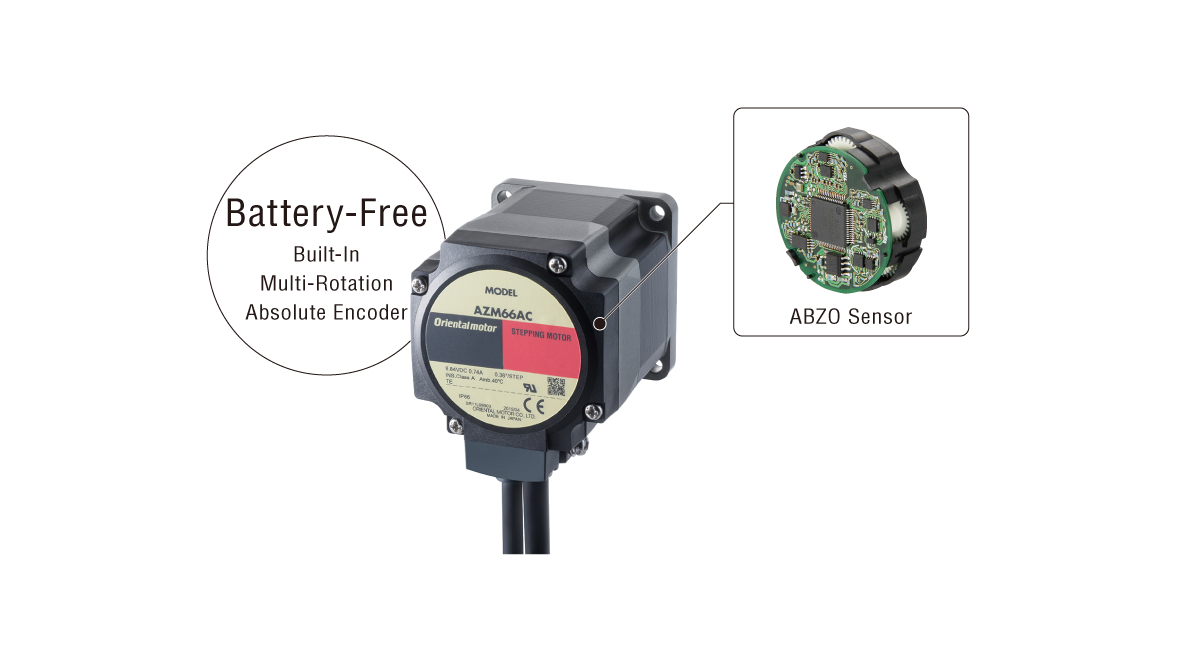

Automated absolute encoder to retain position information

The AZ Series is equipped with a built-in battery-free mechanical absolute encoder <ABZO sensor>. Position information is retained even if the power supply is interrupted by an emergency stop or blackout during positioning operation.

Click here for information about restarting after power supply shut downs

Technical Report RENGA

Technical content that presents useful technical information and Oriental Motor’s product development efforts. This section explains the structure and principles behind the ABZO sensor.

Wide range of products available

A wide range of products is available, offering various frame sizes, torque characteristics, and those with electromagnetic brakes.

The most suitable motor can be selected for each axis.

Driver (Multi-Axis Driver)

Consolidate Drivers to Reduce the Amount of Wiring

The multi-axis driver can connect motors on 2 to 4 axes.

Since the driver can be integrated into a single unit, it is possible to reduce the amount of wiring, such as connection cables to host devices and power supply cables.

Support for a Variety of Motion Networks

MECHATROLINK-III, EtherCAT, and SSCNET III/H driver profile-compatible products are available.

On-Board Equipment

Battery-Free Built-In Absolute Encoder αSTEP AZ Series

αSTEP, which employs Oriental Motor’s unique closed loop control, is equipped with the newly developed ABZO sensor. Absolute mode positioning is now possible without the need for batteries. Advanced positioning is possible at affordable prices.

αSTEP AZ Series Multi-Axis Driver DC Input

This is a multi-axis driver that can be connected to Oriental Motor’s AZ Series DC input motors and electric actuators equipped with such motors. SSCNET III/H, MECHATROLINK-III, and EtherCAT Drive Profile-compatible products are available.

Support for in-House Production of Robots From the Product Selection Stage

Support for Motor Selection

A full-time member of staff will select a motor on your behalf.

Download the Product Recommendation Information Sheet, fill in the required items, and make a request using the email inquiry form* or send it by fax to your local Customer Support Center.

We can work from your own reference materials such as mechanism drawings, notion image, and CAD data.

- * User registration and login are required.

-

< Articulated Robot>

Click here to download the Product Recommendation Information Sheet -

<SCARA Robot>

Click here to download the Product Recommendation Information Sheet <Parallel Link Robot>

Click here to download the Product Recommendation Information Sheet

-

Documentation on Demonstration Unit Available

Information is available on the articulated robot demonstration unit we presented. For information on hardware, such as dimensions and stroke of each axis,

please contact your nearest sales office for more information.

-

Materials for Connecting to PLC Available

Materials for connecting to the network modules of PLCs of leading manufacturers are available. This can save time with program design and startup, so we recommend taking advantage of it.

Click here to download

Service Engineer Visits when Problems Occur

Our service engineers will visit your workplace to respond to any motor-related problems that may occur after the robot is in operation.