Hollow Rotary Actuators DGII Series

DG200R-AZMCD-2

Actuator/Control Circuit

| Product Classification | Product Name | List Price | List Price | Shipping Date |

|---|---|---|---|---|

| Actuator / Control Circuit | DG200R-AZMCD-2 | SGD 4,260 | USD 3,408 | Discontinued Product (31.3.2020 discontinued) |

Included

- Actuator, Circuit, Cable for motor (2 m), Encoder Connection Cable (2 m), Cable for Electromagnetic Brake (2 m), Main Power Supply/Regeneration Resistor Connector (CN4), I/O Signal Connector (CN5), Connector for 24 VDC Power Supply input · Electromagnetic Brake Connector · Regeneration Unit Thermal Input · power removal signal input (CN1), Connection lever, Operation manual

Specifications

Dimensions

Other Specifications

General Specifications (Actuator)

| Installed Motor | AZ Series | |

|---|---|---|

| Operating Environment (When operating) |

Ambient Temperature | 0∼+40°C (Non-freezing)∗ |

| Ambient Humidity | 85% max. (Non-condensing) | |

| Atmosphere | No corrosive gases or dust. No exposure to water, oil or other liquids. | |

| Multi-Rotation Detection Range in Power OFF State (Motor output shaft) |

±900 revolutions (1800 revolutions) | |

- ∗

- According to Oriental Motor’s measurement conditions

Driver Circuit Specifications

| Built-in Controller Type | Pulse input type with RS-485 communication | Pulse input type | ||||

|---|---|---|---|---|---|---|

| I/O function | Maximum Input Pulse Frequency | - | Line driver output from host controller: 1 MHz (at 50 % duty) Open-Collector Output by Host Controller: 250 kHz (at 50 % duty) Negative logic pulse input |

|||

| Number of Positioning Data Sets | 256 points | 256 points* | ||||

| Direct Input | 10 points | 6 points | ||||

| Direct Output | 6 points | |||||

| RS-485 communication remote input | 16 points | - | ||||

| RS-485 communication remote output | 16 points | - | ||||

| Setting Tool | Support Software MEXE02 | ○ | ||||

| Coordinates Management Method | Battery-free Absolute System | |||||

| Operation | Positioning Operation |

Product Line | Positioning Operation | ○ | ○ | ○※ |

| Fastening method | Single-motion Operation | ○ | ○ | ○※ | ||

| Sequential Operation | ○ | ○ | ○※ | |||

| Multistep Speed-Change (Configuration Connection) | ○ | ○ | ○※ | |||

| Sequence Control |

Loop Operation (Repeating) | ○ | ○ | ○※ | ||

| Event Jump Operation | ○ | ○ | ○※ | |||

| Continuous Operation | Position Control | ○ | ○ | ○※ | ||

| Speed Control | ○ | ○ | ○※ | |||

| Torque control | ○ | ○ | ○※ | |||

| Return-To-Home Operation | Return-To-Home Operation | ○ | ○ | ○ | ||

| High-speed return-to-home operation | ○ | ○ | ○ | |||

| JOG Operation | ○ | ○ | ○ | |||

| Monitor/Information | Waveform Monitoring | ○ | ○ | ○ | ||

| Overload Detection | ○ | ○ | ○ | |||

| Overheat Detection (Motor and Driver) |

○ | ○ | ○ | |||

| Position/Speed Information | ○ | ○ | ○ | |||

| Temperature Detection (Motor and Driver) |

○ | ○ | ○ | |||

| Motor Load Factor | ○ | ○ | ○ | |||

| Travel Distance , Cumulative Travel Distance | ○ | ○ | ○ | |||

| Alarm | ○ | ○ | ○ | |||

- *It can be used by setting it with MEXE02 support software.

Circuit General Specifications

|

|

Built-in Controller Type Pulse Input Type with RS-485 Communication EtherNet/IP Compatible EtherCAT Compatible PROFINET Compatible |

Pulse Input Type MECHATROLINK-III Compatible SSCNET III/H Compatible |

|

|---|---|---|---|

| Insulation Resistance |

100 MΩ or more when a 500 VDC megger is applied between the following places:

|

||

| Dielectric Strength |

Sufficient to withstand the following for 1 minute:

|

||

| Operating Environment (When operating) |

Ambient Temperature | 0~+55 °C (Non-freezing)* | |

| Ambient Humidity | 85 % max. (Non-condensing) | ||

| Atmosphere | No corrosive gases or dust. No exposure to water, oil or other liquids. | ||

| Degree of Protection | IP10 | IP20 | |

| Multi-Rotation Detection Range in Power OFF State (Motor output shaft) |

± 900 revolutions (1800 revolutions) | ||

- *When installing a heat sink equivalent to an aluminum plate min. 200×200 mm, thickness 2 mm

Note

- Disconnect the motor and driver when conducting insulation resistance measurements or the dielectric strength test.

Also, do not conduct these tests on the ABZO sensor part of the motor.

RS-485 Communication Specifications

| Protocol | Modbus RTU Mode |

|---|---|

| Electrical Characteristics | EIA-485 Compliant, Straight Cable Use twisted-pair cables (TIA/EIA-568B CAT5e or better recommended). The max. total extension length is 50 m.* |

| Mode | Half duplex communication and asynchronous mode (data: 8 bits, stop bit: 1 bit or 2 bits, parity: none, even, or odd) |

| Transmission Rate | 9600 bps, 19200 bps, 38400 bps, 57600 bps, 115200 bps, and 230400 bps are available. |

| Connection Type | Up to 31 units can be connected to a single programmable controller (master device). |

- *If a specific wiring and layout causes the motor cable or power supply cable to generate a noise problem, shield the cable or use ferrite cores.

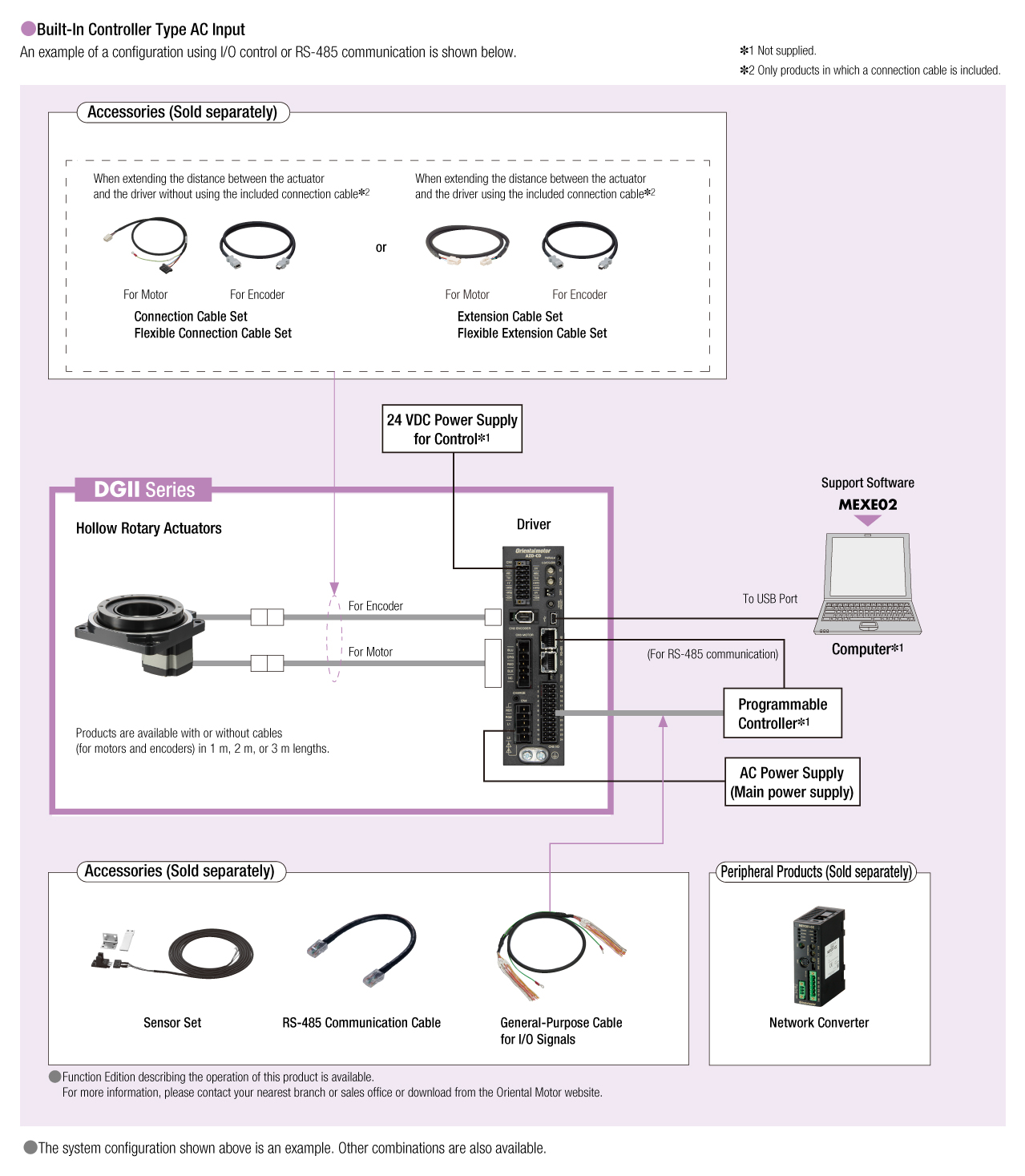

System Configuration

Related Products

| Products | Features | ||

|---|---|---|---|

NETC02-CC

|

Features |

[CC-Link Ver. 2 Compatible] By supporting CC-Link Ver.2, you can simplify the ladder program and shorten the communication time for data sending and receiving. |

|

| Products |

NETC01-CC

|

Features |

[CC-Link Ver.1.1 Compatible] By connecting a network converter, you can complete the wiring process with a single dedicated cable approved for the CC-Link communication protocol. |

| Products |

NETC01-M2

|

Features |

[MECHATROLINK-II Compatible] By connecting a network converter, the wiring process can be completed with a single dedicated cable approved for the MECHATROLINK-II communication protocol. |

| Products |

NETC01-M3

|

Features |

[MECHATROLINK-III Compatible] By connecting a network converter, the wiring process can be completed with a single dedicated cable approved for the MECHATROLINK-III communication protocol. |

| Products |

NETC01-ECT

|

Features |

[EtherCAT Compatible] |

Cables and Accessories