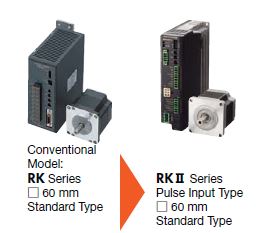

High-efficiency with Low Price.

Compared to the conventional products,

while achieving the significant improvement

in motor performance, easy driver operation

and function, the price has been lowered.

Slim and Compact.

This new driver has been created with rearrangement of the internal components of the previous design, optimizing the usage of the size within the driver. In addition, drivers can be installed side by side, reducing a significant amount of space.

Energy Saving.

By optimizing the motor material, 47% of the power consumption has been reduced. This results in the decrease of electricity and CO2 emission. In addition, with the lower heat generated by the motor, there is a lesser requirement of fans or radiation plate.

Easy Wiring.

The new I/O connector does not require a screw, eliminating the need for soldering or a special crimping tool. The motor connector can be connected easily by using a dedicated cable. This will reduce wiring time, maintenance and prevent mis-wiring.

Easy Selection.

Make your own motor selection for your application by downloading our user friendly motor selection NOW!

http://www.orientalmotor.com.sg/sizingservice/

High Accuracy.

Positioning accuracy of the RKII Series is ±0.05° (± 3 arc min). When the RKII Series is used with a ball screw as shown in the below drawing, the stopping accuracy becomes ±1.4 μm. The accuracy of the normal ground ball screw is ±10 μm, thus the accuracy is high enough for positioning operation.

Low Vibration.

Fulltime micro step driver controlled by a full digital system improve its vibration characteristics much better than ever (first in 5-phase step motor). Current control is also done by a digital system, high spec CPU will perform arithmetic process. This model uses PWM control instead of PAM control, current in each phase became sinusoidal wave. In the result, vibration has been reduced drastically.

Please download our brochure for more information: