Oriental Motor Asia Pacific Pte. Ltd. > Technical Support > Technical Question 12

|

|||

Mr. Vex: A customer wanted me to do the motor selection of the stepping motor for his indexing application. I had ever consulted you about the inertia ratio calculation but when i tried doing it myself, i realized that even AS series motors were not suitable due to high inertia ratio of his application.

Miss Ori: Have you ever considered selecting a geared motor? i suggest you use that for high load inertia application. Refer to the formula in table 2. Choosing a geared motor will reduce the inertia ratio.

Mr. Vex:That is right! I suppose a geared type motor would be compatible with the customer's equipment but it seems difficult to make a choice since there are so many types of geared motors.

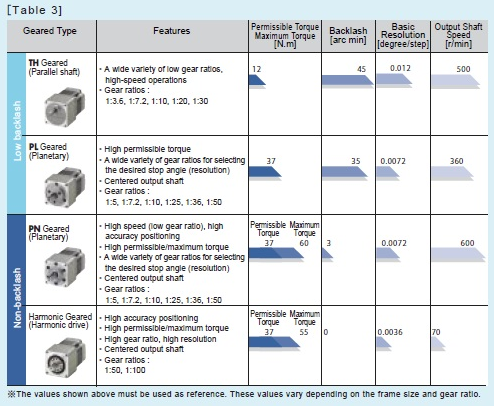

Miss. Ori: You should try comparing the differences of each geared motor. There are charts in the catalogues that you can use for simple comparisons. Take a look at table 3, for example. Can you see the differences?

Mr. Vex: Hmm, permissible torque and amount of backlash are different. If i am not mistaken, "backlash" refers to the freeplay between gears of the gearhead, right?

Miss. Ori: Yes, of course, whether the necessary torque of the equipment is within permissible torque with the level of safely factor to be verified. Besides, the important points are that stepping motors are different from AC motors in positioning accuracy and you can choose the amount of backlash.

Mr. Vex: II see! You cannot just choose a motor by it's inertia ratio and torque. I should suggest the PN and harmonic gears should the customer require highly accurate positioning. Oh, variations in gear ratios are different too depending on the series. Why are there unusual gear ratios such as 1/3.6 and 1/7.2?

Miss. Ori: It is due to the resolution capability of the stepping motor. For example, i wonder how much is the resolution of the motor for

AS series you were thinking of choosing? AS series you were thinking of choosing?

Mr. Vex:Hmm, the

AS Series is 0.36 degree per pulse, right? When it is using gear ratio of 3.6, it becomes 0.1 degree per pulse at the output shaft of the gearhead which makes it easy to achieve a wide variety of angles. AS Series is 0.36 degree per pulse, right? When it is using gear ratio of 3.6, it becomes 0.1 degree per pulse at the output shaft of the gearhead which makes it easy to achieve a wide variety of angles.

Miss. Ori:Right! That was well-considered. In order for it to be accurately divided, you have to choose a gear ratio which will meet the customer's needs. If an indivisible ratio is chosen, the accumulation error gets worse, right?

Mr. Vex:That's right. We must also consider the customer's operational speed. I will select the geared motor in AS Series after i have verified the customer's operational and mechanical.

Miss. Ori: Wait! If the customer's looking for repetitive positioning accuracy, there is always the reduced heat generation and high efficiency for geared motors AR Series. Why not introduce both then?

Mr. Vex:Oh, yes! There is no need to worry about the operation duty cycle in the AR Series too!

|