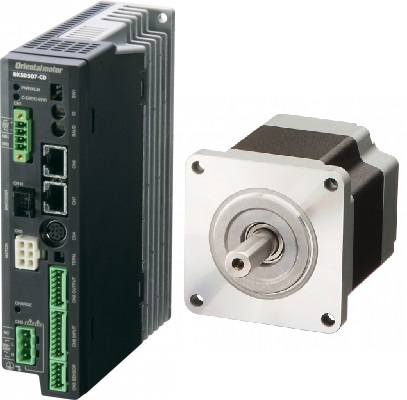

RKII Series (Pulse Input Type)

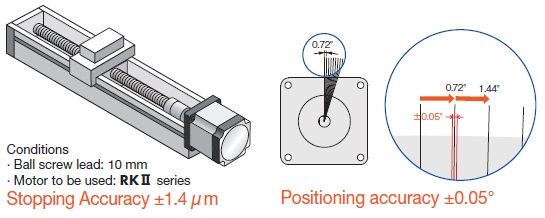

Highly accurate and positioning operation

Positioning accuracy of the RK II Series is ±0.05˚ (±3 min). When using a ball and screw together as shown in the right drawing, the stopping accuracy becomes ±1.4 μm. The accuracy of the normal ground ball screw is ±10 μm, thus the accuracy is high enough for positioning operation.

High Efficiency and low price

Compared to the conventional products, while achieving the significant improvement in motor performance, easy driver operationand function, the price has been lowered.

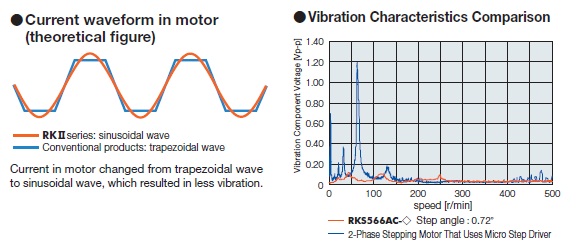

Vibration is drastically reduced

By changing a driver to each- phase detecting PWM control method, the motor current can now be controlled in the sinusoidal way.Therefore, vibration is drastically reduced.

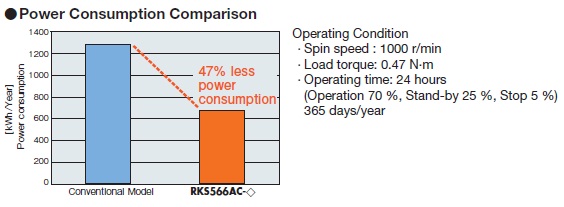

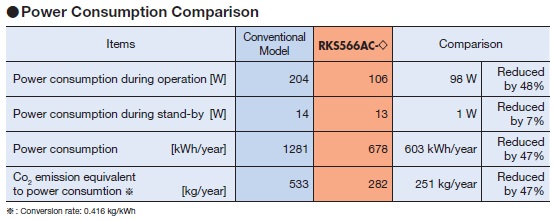

Reduced power consumption by up to 47%

By optimizing the motor material, 47% of the power consumption has been reduced. This results in the decrease of electricity and CO2 emission.In addition, with the lower heat generated by the motor, there is a lesser requirement of fans or radiation plate.

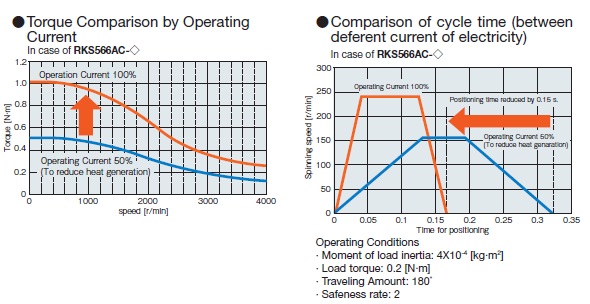

Reduced positioning time

In a conventional stepping motor, one way to suppress heat generation is to lower the operating current. By doing so, the positioning time would be longer, as the torque is lower. The RK II Series is a low-heat, high-efficiency motor. It is able to reduce the position timing by fully utilizing the motor torque.There is no need to reduce the operating current.

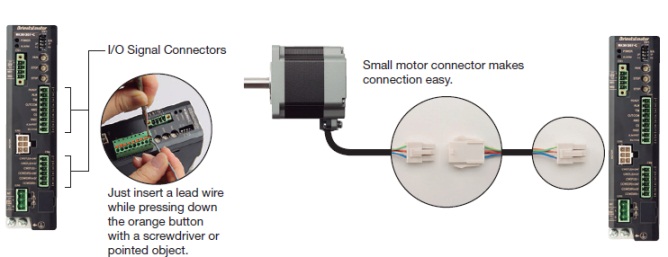

Easy Wiring

The new I/O connector does not require a screw, eliminating the need for soldering or a special crimping tool. The motor connector can be connected easily by using a dedicated cable. This will reduce wiring time, maintenance and prevent mis-wiring.

Optimal Resolutions can be selected

Evolved from 16 step angles of the previous driver, the new RKII Series comes with a wider selection of 32 step angles. Users can also select the step angles of a 2-Phase Stepping motor with this driver. Simply select the desired step angle with the step angle setting switch, without the use of any software or control modules.

Improved Motor for Easier Use

9 different types of protective functions have been installed to aid the user whenever an error occurs. When an error occurs, the Alarm LED will start blinking. The error can be easily identified by counting the number of blinks.

● Main circuit(overheating)

● Overvoltage

● Command pulse(abnormality)

● Over current

● Under voltage

● Electrolytic capacitor(abnormality)

● EEPROM abnormality

● CPU abnormality

● Automatic control of electromagnetic brake(abnormality)

For brochure download, please click here